Sheetmetal, Metalforming, Welding

Metals are essential materials in industries. Discover all the equipment and machines which will facilitate and improve your sheet metal and metal processing work on our site.

A few definitions

Sheet metal working is a metal manufacturing process which consists in producing very thin steel sheet. The means used is rolling, which can be carried out hot or cold. It should be noted that there is a big difference between industrial sheet metal working and fine sheet metal working. The latter is used to manufacture very thin parts, individually or in small series.

Metal shaping, for its part, concerns the various techniques used to give materials a clearly defined shape. For metal processing, for example, the main shaping processes are forging, foundry, sintering and drawing. We must also distinguish forming (hot forming, cold forming and electromagnetic forming), which is another manufacturing process used to shape a by-product.

Categories of sheet metal and metal shaping equipment

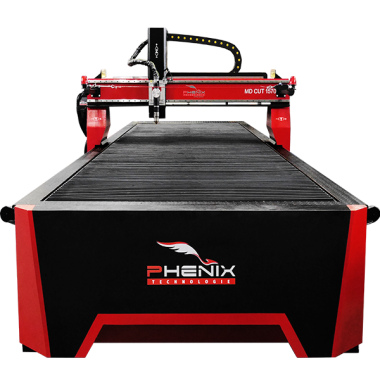

Industrial sheet metal manufacturing requires the use of different machines such as tube cutting machines and plasma, water jet, laser or oxygen cutting machines. A wide variety of shearing machines may also be needed: circular shearing machines, gusset-cut shearing machines, hydraulic guillotine shearing machines, etc.

It is necessary to use tools such as deep-drawing machines, bending presses, punching machines, etc. Lastly, you will find other equipment and accessories on the site such as the lubricant and the rust remover and passivator which you can use to maintain your machines.

Our referenced suppliers

Our community includes the best manufacturers, suppliers, subcontractors and consulting firms for sheet metal and metal shaping: Girardeau, Sotraban, DEF TEC, CONEXMA, REVOLUPLAST and Etablissement DELABRE, etc.

Français

Français