Pourquoi les ultrasons sont le chaînon manquant de votre programme de maintenance prévisionnelle

La maintenance prévisionnelle est devenue la norme pour garantir l’efficacité et la fiabilité des opérations dans l’industrie moderne.

Alors que les usines s’efforcent de réduire les temps d’arrêt imprévus, de prolonger la durée de vie des équipements et d’optimiser l’efficacité énergétique, des technologies telles que la thermographie infrarouge, l’analyse des vibrations et l’échantillonnage d’huile ont acquis une grande notoriété. Mais même parmi les entreprises qui maîtrisent bien ces méthodes, il existe un outil puissant et souvent sous-utilisé : les ultrasons.

L’inspection par ultrasons comble les lacunes critiques de votre stratégie de surveillance de l’état des équipements. Elle écoute là où les autres technologies regardent. Ce faisant, elle apporte clarté, rapidité et facilité d’action à des inspections qui étaient autrefois remplies de conjectures.

Alors que les usines s’efforcent de réduire les temps d’arrêt imprévus, de prolonger la durée de vie des équipements et d’optimiser l’efficacité énergétique, des technologies telles que la thermographie infrarouge, l’analyse des vibrations et l’échantillonnage d’huile ont acquis une grande notoriété. Mais même parmi les entreprises qui maîtrisent bien ces méthodes, il existe un outil puissant et souvent sous-utilisé : les ultrasons.

L’inspection par ultrasons comble les lacunes critiques de votre stratégie de surveillance de l’état des équipements. Elle écoute là où les autres technologies regardent. Ce faisant, elle apporte clarté, rapidité et facilité d’action à des inspections qui étaient autrefois remplies de conjectures.

Entendre ce que les autres loupent

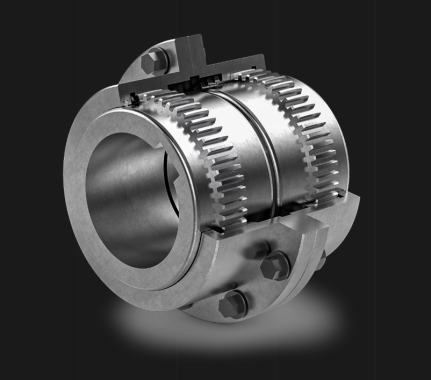

Chaque équipement raconte une histoire, si vous savez écouter. Avant de tomber en panne, un roulement commence à émettre un bruit différent. Avant d’être défaillant, un purgeur vapeur cesse d’émettre le bruit normal. Avant de provoquer une panne catastrophique, un arc électrique à l’intérieur d’un panneau commence par émettre un léger bourdonnement électrique. La technologie ultrasonore permet aux inspecteurs de détecter ces signes avant-coureurs, bien avant que la panne ne se produise.

Cela est particulièrement important dans les environnements où l’accès visuel est limité. Par exemple, les armoires électriques ne peuvent pas toujours être ouvertes en toute sécurité. Mais grâce aux ultrasons aériens, il est possible d’entendre les arcs électriques, les traînées ou les effets corona depuis l’extérieur du panneau, ce qui permet aux inspecteurs de rester en sécurité tout en leur fournissant des informations précieuses.

De même, les systèmes à air comprimé et à gaz sont réputés difficiles à surveiller visuellement. Des fuites peuvent se produire dans des zones difficiles d’accès, passer inaperçues pendant des mois et entraîner discrètement des pertes d’énergie se chiffrant en milliers d’euros. Mais ces fuites font toujours du bruit. Grâce aux ultrasons, même la plus petite fuite devient instantanément détectable, quelle que soit sa distance ou son degré de dissimulation.

Chaque équipement raconte une histoire, si vous savez écouter. Avant de tomber en panne, un roulement commence à émettre un bruit différent. Avant d’être défaillant, un purgeur vapeur cesse d’émettre le bruit normal. Avant de provoquer une panne catastrophique, un arc électrique à l’intérieur d’un panneau commence par émettre un léger bourdonnement électrique. La technologie ultrasonore permet aux inspecteurs de détecter ces signes avant-coureurs, bien avant que la panne ne se produise.

Cela est particulièrement important dans les environnements où l’accès visuel est limité. Par exemple, les armoires électriques ne peuvent pas toujours être ouvertes en toute sécurité. Mais grâce aux ultrasons aériens, il est possible d’entendre les arcs électriques, les traînées ou les effets corona depuis l’extérieur du panneau, ce qui permet aux inspecteurs de rester en sécurité tout en leur fournissant des informations précieuses.

De même, les systèmes à air comprimé et à gaz sont réputés difficiles à surveiller visuellement. Des fuites peuvent se produire dans des zones difficiles d’accès, passer inaperçues pendant des mois et entraîner discrètement des pertes d’énergie se chiffrant en milliers d’euros. Mais ces fuites font toujours du bruit. Grâce aux ultrasons, même la plus petite fuite devient instantanément détectable, quelle que soit sa distance ou son degré de dissimulation.

Simple, mais extrêmement efficace

L’un des principaux atouts de l’ultrason réside dans son accessibilité. Contrairement à certaines technologies avancées qui nécessitent une grande expérience ou une interprétation complexe, l’ultrason est intuitif. Un technicien peut commencer à l’utiliser efficacement après seulement quelques jours de formation, ce qui en fait l’une des technologies les plus rapides à déployer au sein d’une équipe.

Mais ne vous laissez pas tromper par sa simplicité, l’ultrason fournit des informations approfondies. Il permet non seulement de détecter les problèmes, mais aussi de quantifier leur gravité. Par exemple, les techniques de lubrification basées sur le son permettent aux inspecteurs d’identifier le moment précis où un roulement a besoin d’être graissé, évitant ainsi une lubrification insuffisante ou excessive. Cela se traduit par une meilleure fiabilité, moins de gaspillage de lubrifiant et une durée de vie plus longue des équipements.

L’un des principaux atouts de l’ultrason réside dans son accessibilité. Contrairement à certaines technologies avancées qui nécessitent une grande expérience ou une interprétation complexe, l’ultrason est intuitif. Un technicien peut commencer à l’utiliser efficacement après seulement quelques jours de formation, ce qui en fait l’une des technologies les plus rapides à déployer au sein d’une équipe.

Mais ne vous laissez pas tromper par sa simplicité, l’ultrason fournit des informations approfondies. Il permet non seulement de détecter les problèmes, mais aussi de quantifier leur gravité. Par exemple, les techniques de lubrification basées sur le son permettent aux inspecteurs d’identifier le moment précis où un roulement a besoin d’être graissé, évitant ainsi une lubrification insuffisante ou excessive. Cela se traduit par une meilleure fiabilité, moins de gaspillage de lubrifiant et une durée de vie plus longue des équipements.

Quand la formation fait la différence

C’est là qu’intervient la formation de certification de niveau 1 de SDT. Pendant deux jours et demi, les participants sont guidés à travers une expérience d’apprentissage riche qui combine des bases théoriques claires et des instructions pratiques.

Le cours est conçu non seulement pour enseigner le fonctionnement des ultrasons, mais aussi pour renforcer la confiance dans leur utilisation efficace dans un large éventail d’applications. Les participants apprennent comment le son se propage dans l’air et les structures, comment interpréter ce qu’ils entendent et comment prendre des décisions éclairées sur la base de ces résultats.

Qu’il s’agisse de localiser des fuites d’air comprimé, de détecter les premiers signes de défaillance mécanique, d’évaluer l’état des purgeurs vapeur et des vannes hydrauliques ou d’identifier les décharges électriques sans ouvrir les panneaux, la formation de niveau 1 fournit les outils et les connaissances nécessaires pour effectuer des inspections plus rapides, plus sûres et plus efficaces.

C’est là qu’intervient la formation de certification de niveau 1 de SDT. Pendant deux jours et demi, les participants sont guidés à travers une expérience d’apprentissage riche qui combine des bases théoriques claires et des instructions pratiques.

Le cours est conçu non seulement pour enseigner le fonctionnement des ultrasons, mais aussi pour renforcer la confiance dans leur utilisation efficace dans un large éventail d’applications. Les participants apprennent comment le son se propage dans l’air et les structures, comment interpréter ce qu’ils entendent et comment prendre des décisions éclairées sur la base de ces résultats.

Qu’il s’agisse de localiser des fuites d’air comprimé, de détecter les premiers signes de défaillance mécanique, d’évaluer l’état des purgeurs vapeur et des vannes hydrauliques ou d’identifier les décharges électriques sans ouvrir les panneaux, la formation de niveau 1 fournit les outils et les connaissances nécessaires pour effectuer des inspections plus rapides, plus sûres et plus efficaces.

Une certification qui donne des résultats concrets

À la fin de la formation, les étudiants passent un examen écrit et pratique. Les inspecteurs certifiés de niveau 1 retournent ensuite dans leurs usines avec la capacité d’apporter immédiatement de la valeur ajoutée. Ils sont équipés pour trouver et corriger les inefficacités cachées, prévenir les pannes coûteuses et contribuer à la fiabilité à long terme de leur installation.

Pour les organisations, cela se traduit par un retour sur investissement rapide. Le coût de la formation est rapidement amorti par les économies générées grâce à la réduction des pertes d’énergie, à l’amélioration des performances des actifs et à la diminution des arrêts imprévus. Pour les inspecteurs, cela signifie la possibilité de se développer professionnellement et d’être fiers de jouer un rôle essentiel dans la stratégie de maintenance.

À la fin de la formation, les étudiants passent un examen écrit et pratique. Les inspecteurs certifiés de niveau 1 retournent ensuite dans leurs usines avec la capacité d’apporter immédiatement de la valeur ajoutée. Ils sont équipés pour trouver et corriger les inefficacités cachées, prévenir les pannes coûteuses et contribuer à la fiabilité à long terme de leur installation.

Pour les organisations, cela se traduit par un retour sur investissement rapide. Le coût de la formation est rapidement amorti par les économies générées grâce à la réduction des pertes d’énergie, à l’amélioration des performances des actifs et à la diminution des arrêts imprévus. Pour les inspecteurs, cela signifie la possibilité de se développer professionnellement et d’être fiers de jouer un rôle essentiel dans la stratégie de maintenance.

Un investissement judicieux

À une époque où l’excellence opérationnelle se mesure en minutes gagnées, en kilowatts économisés et en pannes évitées, l’inspection par ultrasons n’est plus une option… elle est indispensable. Et la clé pour exploiter tout son potentiel réside dans la formation.

Si vous êtes prêt à écouter ce que vos machines essaient de vous dire, il est temps d’intégrer les ultrasons au cœur de votre programme de maintenance. Il est temps d’obtenir votre certification.

À une époque où l’excellence opérationnelle se mesure en minutes gagnées, en kilowatts économisés et en pannes évitées, l’inspection par ultrasons n’est plus une option… elle est indispensable. Et la clé pour exploiter tout son potentiel réside dans la formation.

Si vous êtes prêt à écouter ce que vos machines essaient de vous dire, il est temps d’intégrer les ultrasons au cœur de votre programme de maintenance. Il est temps d’obtenir votre certification.

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français