Bolt tightening techniques (introduction)

In this news, we will see the different bolt tightening techniques for industrial screwed assemblies.

Today, we are going to question the nature and operating principle of a screw.

Introduction

This article aims to present a complete overview of tightening and screwed assemblies in the industrial field. After reviewing commonly used methods for tightening bolts, we will explore how TRAXX products and services provide an innovative solution for measuring the tightening tension of complex bolted assemblies.

I. What is a screw?

Screws play a role in a multitude of applications: from the stapler to the structure of a building, from the cylinder head of an engine to Ariane 6 rockets. If a bed base that unscrews can be annoying, the detachment of an Ariane 6 rocket launcher in flight represents a much more serious problem. The key lies not only in tightening, but also in the correct way to do it. First of all, it is essential to understand the function and mechanism of screws.

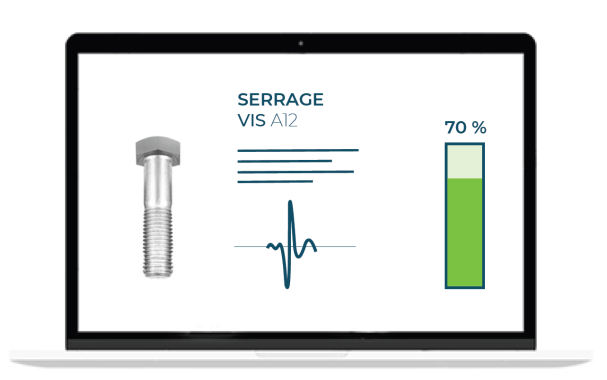

To join two parts, they are tightened together using bolts, thus creating a pressure force between them. By turning the nut, which advances along the helical thread of the screw towards its head, the two parts are compressed. During this process, the screw stretches under the stress of tightening, much like a rubber band under tension.

To better visualize this, imagine a rubber band stretched between your fingers. The force that pulls your fingers together is due to the traction exerted by the rubber band, seeking to return to its original shape. Likewise, in a screwed assembly, the screw tends to return to its initial, untightened state. The tensile force in the screw is equivalent to the compressive force between the assembled parts.

To measure this force, we use Newton's unit. The clamping force required for a box spring is much less than that required for an Ariane 5 rocket, where the forces involved are gigantic. For example, a bolt in an automobile engine cylinder head can support a load of 5 tonnes, equivalent to a force of 50 kN. When a screw experiences a force of 5 tons, the parts are compressed by a similar force. Thus, tightening a screw corresponds to the application of a measurable force.

In the industrial field, this translates into what is known as "clamping tension".

In summary, the screw is subjected to tension while the screwed assembly is subjected to compression. But how to carry out this tightening correctly? There are different methods and techniques for tightening bolts, each with varying effectiveness.

The rest of this article will focus on the different bolt tightening techniques on the market .

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français