BARCODIS

ETI 3000 2A

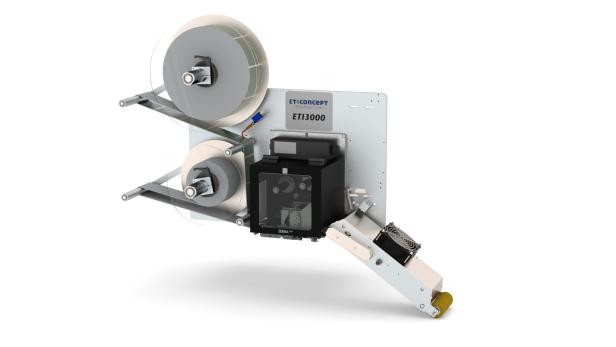

– Printing system for pallets – Installation by cylinder on 1 or 2 adjacent faces Manufactured by Eticoncept, the real-time ETI 3000® 2A system includes a printing module and a pneumatic applicator allowing adhesive label printing and immediate installation of it by "Turbo-jet" on a moving or stationary object with or without physical contact with the pallet. The application of the front or rear labels is ensured by a rotating applicator arm with or without stopping the pallet, the lateral application is carried out by a linear cylinder with or without stopping the pallet. The advantages in controlling the manufacturing process: 100% Eticoncept machines, the result of more than 15 years of experience in the field Total control of the design and system components Flexibility for modifications and adaptation to your needs Competitive prices A single stock for right or left machine due to its symmetrical design Base common to all current and future applicators

Logistics Agri-food Manufacturing industries Chemistry – Pharmaceuticals – Cosmetics

Characteristics of the pneumatic applicator: Pneumatic applicator for applying the label is detached from its support, then sucked up by the application plate and placed on the pallet. Deposit speed up to 3 pallets per minute. Double jack for front and side laying Standard jack length 550 mm for side laying (ISO jack) 470 mm usable Arm length for front laying: 640 mm usable Label size: 150 x 210 mm (other sizes on request) Diameter roll of 350 mm labels on 76 mm mandrel (600 m long) i.e. approximately 3000 150x210 mm labels. Starters

Français

Français