KUK Group - Des bobinages exigeants sur mesure

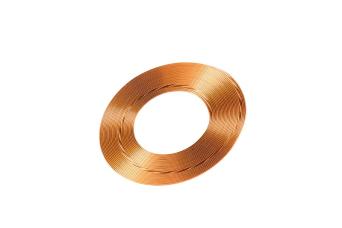

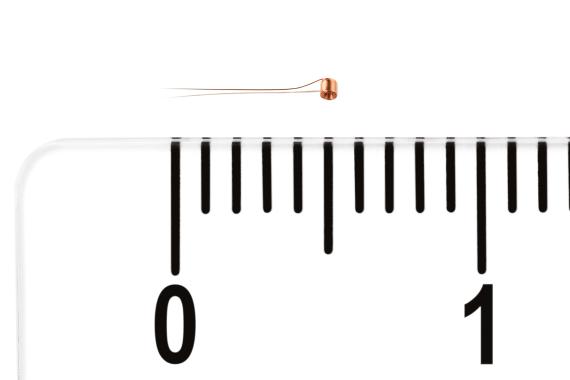

Air chokes

KUK manufactures air coils for a wide variety of applications, e.g. RFID antennas, control coils or transponder coils. To produce self-supporting coils, self-bonding wire is also used, which is superficially bonded (glued) together during or after winding.

Air coils are usually made of enamelled copper wire or high-frequency litz wire. So-called self-bonding wire is used to manufacture self-supporting air coils. It has an outer layer whose melting point is lower than the melting point of the insulation. After winding the air core coil, the turns of the coil are "baked" (glued) together by heating, usually by increased current flow.

Thanks to our in-house plant engineering, we can optimally align our production lines to your needs, even for air core coils.

- Layered winding

- Stable winding at high temperature

- Reinforced, twisted winding end

- Tinned wires

- Varnished copper wires

- High temperature

- Aluminum wires (copper)

- Stranded wires

- Round, rectangular, oval...

- Single layer flat coils

- Specialty: Patented spool whose starting wire and finishing wire are located on the outside diameter of the spool.

Français

Français