RB SYSTEM

Molybdenum continuous wire electroerosion cutting machine

Description

The wire used is generally Ø0.18mm, wound on a drum located at the rear of the machine. The wire will come and go to cut the part which is fixed on the work table without coming into contact with the material. The strong rigidity of the wire allows a long autonomy (approximately 40h) but also to avoid the often too frequent breakages.

Operating by spraying and offering working dimensions of up to 800x600mm, our machine offers many advantages:

- Very low cost of use (~0.50€/h)

- Good accuracy (≤0.6μm)

- Good surface condition (Ra ≤0.8)

- Higher cutting speeds than EDM machines

- classics

- Possibilities of cutting poorly conductive metals (ceramic,

- edge carbide, glassy carbon,...)

- Easy to use

- Long cutting autonomy (~40h)

- Quick and easy manual threading

- Support for DXF, DWG files

- Very high thread tension (~1724 N/mm2) to prevent breakage and

- ensure non-stop productivity

- No wire elongation (<2%) during cutting

- Electric probe for part probing

- Moving digital axes with a remote control

RB SYSTEM

Sheetmetal, Metalforming, WeldingDescription

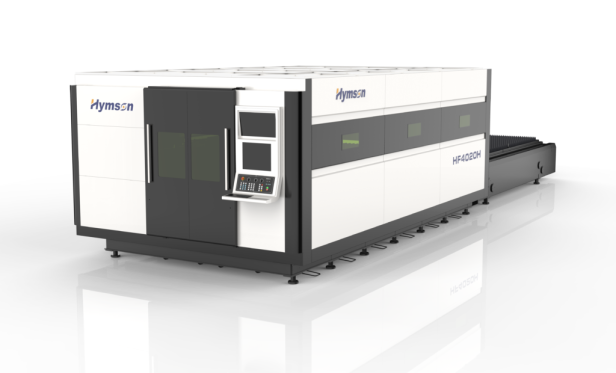

Molybdenum Continuous Wire EDM Machines Fiber laser cutting machines Fiber, MOPA and CO2 laser marking machines Laser micromachining machines (nano, pico and femtosecond) Water jet micro-cutting machines Equipment and clamping for EDM machines Wire, filters, wear parts for EDM machines Deionization and demineralization without resins

Français

Français