Machining and material removal

As regards machining and material removal, it could be said that industries and companies are constantly changing the production systems. This is because more and more of them are automating tasks by using more efficient machine tools and robots.

A few definitions

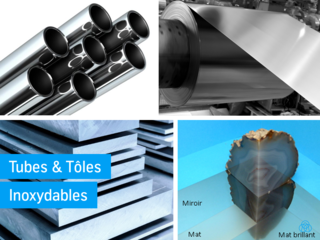

By machining and material removal we mean a mechanical part manufacturing process which consists in working on a plate or by blocking by removing chips. High-precision parts can thus be produced with the required shapes and dimensions. Naturally, all of this is done using machine tools.

There are also various techniques such as milling, reaming, screw-cutting, drilling, cutting, turning and electrolyte machining. And all these techniques can be used on all types of materials: wood, composite, plastic and metal.

Categories of machining and material removal equipment

The equipment category consists of the various machine tools. This includes bi-spindle single-turret turning centers, horizontal-spindle grinding machines, horizontal machining centers with palletizing, machining centers, high-speed milling machines, etc.

The peripherals and accessories category includes chucks, mechanical and magnetic plates, lifting tables, inserted-blade milling cutters, etc.

Lastly, you will find a list of a number of companies who can provide you with their know-how. They offer many different services: broaching, sharpening, reaming, peeling, spark erosion, balancing, threading, drilling, chemical etching, etc.

Our referenced exhibitors

We receive thousands of visitors every day and have a large community consisting of suppliers, manufacturers and experts from consulting firms.

In addition, if you visit our permanent virtual showroom you will note that we work with the best suppliers to satisfy our most demanding customers.

Français

Français