Conversion CO2 - FIBER

Our company is specialized in the conversion of Bystronic or Trumpf CO2 laser machine in FIBER version.

We call this the "Second Life". From 3Kw to 12Kw Fiber, all needs are covered.

Regarding Bystronic machines, we cover CNC96, Byvision, Byvision Cutting, all types of machines and formats, Bystar, Bysprint, Byspeed ect...

We have also developed our fiber interface for Trumpf machines.

The CO2 laser has dominated the industry in the past. However, this trend could not prevail as fiber laser technology has advanced for many years. Your existing machinery is generally still in good condition, but has gaps in its basic technology. That is why we start and replace the laser source and laser head as well as other components and can then use the many advantages of fiber laser technology in the existing system.

Benefits of renovation

No major machine changes;

No modification of the control system;

Much less maintenance;

No need for laser gas (He, CO2, N2);

Reduction of electricity costs by approximately 50%;

Faster cuts in the thinnest area up to 400%;

Maintenance times are reduced;

Retain cutting process settings;

Cutting of reflective metals, copper, brass; Maintenance costs saved on average around 40,000 euros per year (depending on the year);

Refurbishment solution

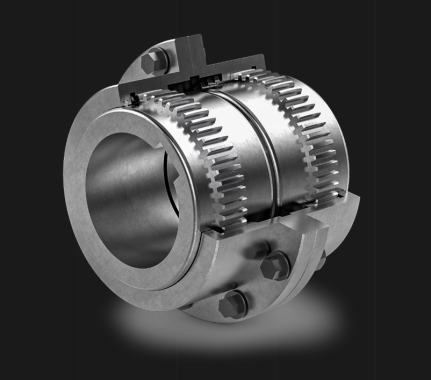

We will install the new fiber laser source, fiber laser cutting head, cooling machine, drive chain, interface controller system and other safety devices on Bystronic CO2 laser cutting machine of origin. This solution will keep the advantages of Bystronic machine, such as excellent dynamic performance, high precision, easy operation, convenient maintenance, etc. We will solve the high maintenance cost of original carbon laser source problems with our technology.

Why did you choose our solution?

1, we developed the Bystronic machine retrofit solution in 2019, and the first machine has been working with our system for 3 years. There are more than 150 sets of machines working with our system in China, and about 37 sets of machines in Europe, 36 overseas. (From 08/2022);

2, we are building a global maintenance department and storage center in our partner factory in Poland. We supply 1 new EU stock controller and fiber laser source system to solve fiber source shutdown issues under warranty in case of failure.

3, We have many partners to work with us in the world, and they are professional with Bystronic maintenance, cutting process. We can also provide them with CNC spare parts.

4, Customer can get quick return with our solution, it is the best investment for their Bystronic machine.

5, The customer starts a second machine life with a guarantee on the resonator, the cooler, the interface as well as the cutting head.

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français