AGC BUSINESS CONSULTING SA

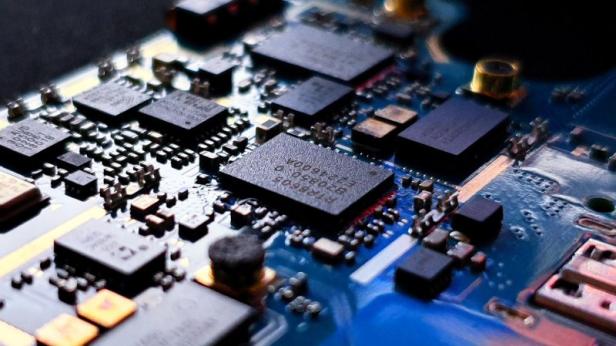

Electronics

AGC offers the supply of quality cables and electronic components.

– Certifications: EU / Rohs / Reach / UL / FCC / IP67

– Flexibility: short deadlines, small and medium quantities of orders accepted

– Serial products & production on demand according to your specifications

ELECTRONIC BOARD ASSEMBLY SERVICES (EMS)

Looking for an expert for the manufacture of assembled electronic boards? AGC exports electronic circuits to more than 30 countries.

Our field of possibilities for electronic cards (printed circuits)

AGC offers a wide range of electronic boards:

- Single-sided (components assembled only on top of the PCB)

- Double-sided (components on both sides to reduce clutter)

- Aluminum cards (for better heat dissipation)

- Plastic (FR1/XPC/FR4/CEM1/CEM3)

- Multi-layer maps (up to 50 layers)

- Flexible Maps

- HDI (High Density Interconnects; Type I, Type II, Type III)

- Rigid / Rigid-Flexible

- Size of cards from a few mm to 500x500mm

We offer printed circuits up to 500x500mm with all possible vias: via-in-PAD, through-holes, blind vias, buried vias.

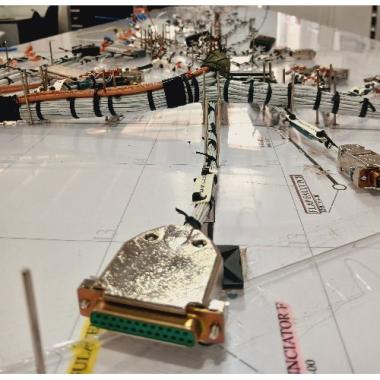

Electronic Circuit Assembly Capabilities (PCBA)

Our capabilities include all the most common processes, which allows us to respond to more than 95% of our customers' requests for quotations. By offering SMT (Surface Mounted Components) or manual assembly, we can go down to component size 01005 on our RoHS wave soldering lines or manual assembly lines.

If you need to protect your cards against the elements (dust, water – IP67/IP68) we can offer varnishing of the electronic cards or potting.

Also benefit from our mechanical skills to carry out the final assembly of your products with the boxing of your cards (plastic, metal or other).

Sourcing of electronic components

The availability of electronic components of a BOM can be a key point in the manufacturing time of electronic boards, for this we offer our support services for the identification of sources of electronic components.

The assembly of electronic cards in China is even more interesting ( cost reduction ) with the replacement of certain non-critical components by local quality components, we offer this service during the analysis of your nomenclature.

The use of local components (China / Asia) also makes it possible to reduce the lead time and therefore the PCBA manufacturing lead time.

Additionally, some electronic component suppliers have regional distribution organizations, with components only available or cheaper in ASIA/China compared to the rest of the world.

Quality control of assembled electronic circuits.

Depending on the projects and your needs, we can carry out the quality tests below:

- Automatic Optical Inspection

- X-ray inspection of welds

- RoHS test spectrometer for components – XRF (verification of the presence of prohibited elements)

- 3D weld testing machine

- Functional tests

- Visual inspection according to IPC-600 /610

- Nail board (ICT)

- Aging tests

Français

Français