PRACARTIS GROUPE

Machine rebuilding, improvement and optimization

Description

Technical details

COMPLETE OR PARTIAL RETROFIT OF SPECIAL MACHINING AND GRINDING MACHINES

- Electrical renovation (replacement of CNC, control panel, electrical cabinet, boxes, cable harnesses and chains, electrical sub-assemblies, rulers and encoders, repair and replacement of speed controllers, etc.)

- Mechanical renovation (guides, transmissions, heads, feed boxes, turrets, spindles, electrospindles, mechanical subassemblies , re-geometry, etc.)

- Total or partial renovation of hydraulic subassemblies

- Total or partial replacement of obsolete equipment

IMPROVEMENT

- Addition of features and equipment ( lubrication center, tool magazine, conveyor, suction, automatic parts loader, probes, control cameras, etc.)

- Predisposition for AI – adaptive and autonomous machine

OPTIMIZATION

- Improving machine performance and precision, managing and reducing energy consumption, improving machine reliability, etc.

- Improved performance, capabilities, usability and maintainability

SECURITY

- CE conformity

- Upgrading to standards

- Risk analysis

- Calculation notes

- Safety file

- Accompaniement

- technical choice in the compliance of machines

- Machine Safety Expert (CMSE)

TRAINING

Administrative documents

PRACARTIS GROUPE

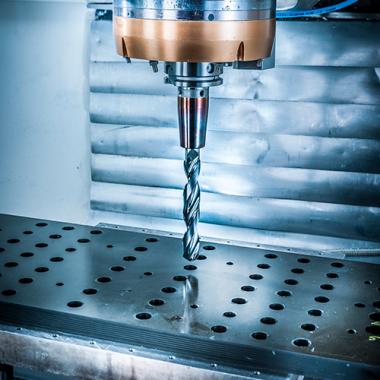

Machining and material removalDescription

The PRACARTIS Group is a French player recognized for the manufacture of specific cutting tools, as well as the maintenance, manufacture and distribution of electrospindles. PRACARTIS is now expanding its range of products and services for precision machining and is firmly committed to sustainable industry. Thus, the PRACARTIS group is unveiling...

Français

Français