GINDRE

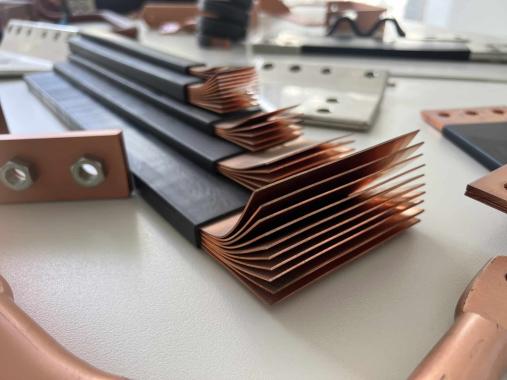

Copper components

From the raw material transformed by our extrusion, drawing and rolling processes, Gindre produces components in copper and copper alloys by adapting to the most demanding technical constraints. Whether in machining and turning, punching and bending, cutting, die-stamping, our technical teams develop new products in close collaboration with our customers. We also offer insulation, surface treatment and sub-assembly assembly options. By combining a personalized logistics solution, we allow our customers to focus on their core business.

Whether companies wish to outsource production or are looking for ready-to-use components , the integrated industrial organization at Gindre (from material to component) and all the technologies available within the various workshops in Europe and around the world guarantee them:

- have parts that are perfectly adapted to their needs and technical requirements each time

- save money on their supply chain by rationalizing the materials used and their supply as best as possible

- reduce their stocks and administrative formalities…

Based on specifications , the design office teams define the material suited to the need and the basic profile will most often be manufactured specifically.

They develop and design the optimum processes and tools appropriate for the production of the expected part, whether classic or special. To do this, they combine technical know-how and traditional or cutting-edge production methods that will be managed by experienced professionals.

The technologies available for use with copper and various copper alloys include:

cutting, follow-up cutting, punching, bending, turning, tapping, CNC machining, sheet metal nibbling, water jet cutting, brazing, sheathing, surface treatment (silver plating, tin plating, nickel plating, gold plating), epoxy, insert, assembly, kitting, etc.

Français

Français