FIVES NORDON

INDUCTION BENDING

MASTERY OF THE BENDING PROCESS: GEOMETRY, METALLURGY AND MECHANICS

Fives' Piping Solutions offering has developed its expertise in hot bending of carbon and stainless steels for 40 years, while constantly improving its performance and technicality.

Fives' Piping Solutions offer has worldwide experience in the prefabrication and assembly of HP, MP, BP piping for the chemical - petrochemical industry, thermal or nuclear power plants and offshore.

Induction bending is one of the essential operations. Thanks to its complete mastery of processes covering all grades of carbon, alloy or stainless steel, Fives has developed its expertise in hot bending by constantly improving its performance and technicality.

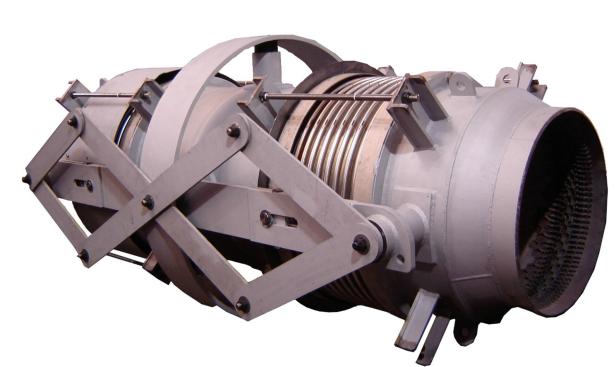

CAPACITIES OF THE COJAFEX PB 1000 BENDING MACHINE EQUIPPED WITH THE “START-STOP” SYSTEM

The method provides the possibility of bending welded tubes, seamless tubes, HEB-U profiles or others of all sections, square tubes, etc.

Our method applies to the following materials:

— Carbon steel (API 5L X42-52-60-65-70, P265GH, P295GH...)

— Stainless steel (ASTM A 312 TP 304, 309, 316...), Duplex, SuperDuplex

— Alloy steel (ASTM A 335 Gr P11, P22, P5, P9, P9.1, P9.2, X20, 15CD205, 15Mo3, 15NiCuMo)

— Inconel 625, Incolloy 600H

— Cladded tubes

Abilities | Minimum | Maximum |

Outer diameter (D) | 88.9 mm | 1016 mm |

thickness (e) | 5.5 mm | 100 mm |

Bending angle ( a ) | 0° | 180° |

Bending radius (R) | 250 mm | 5 100 mm |

Tube length | | 12,500 mm |

An integrated control service

Tube inspection upon receipt

Mechanical tests on qualification hangers and witness coupons

Metallurgical checks

Dimensional control on marble

Magnetic particle or penetrant inspection

Ultrasonic control

X-ray control

Hydraulic test up to 10,000 bar

Spectroscopy...

Other services

Supply of mother tubes

Coating

Shot blasting, polishing

Pickling, passivation

Heat treatments (hyperquenching, normalization, tempering, etc.)

Chamfering, boring

Packaging and shipping of finished products

Français

Français