NORELEM

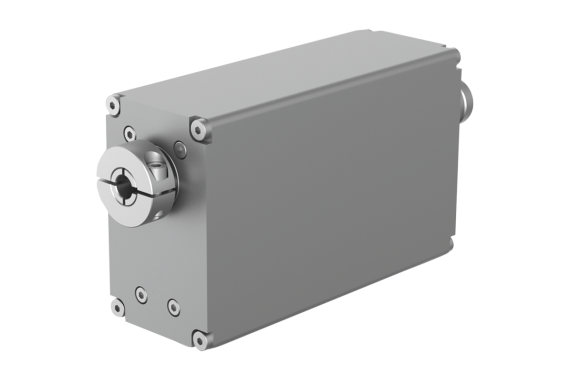

Stainless steel or aluminum servomotors for linear units

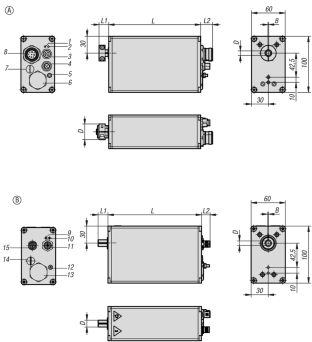

Servo motors are complete mechatronic systems. They consist of a battery-free multi-turn sensor, a gear and a motor, as well as integrated power and control electronics. Servo motors are intelligent adjustment units that can be mounted at the end of a machine shaft or on a machine shaft or spindle. They convert the received movement commands into mechanical rotational movements, thus driving the machine shaft. To prevent the drive from rotating with the machine shaft, the mounting kit (85000-51) consisting of a torque take-up arm and a mounting bracket is used.

Matter :

Stainless steel or aluminum case.

Stainless steel adapter.

Note:

Servo motors require two supply voltages in the range of 24 to 30 V DC.

Their drives are equipped with a mechanical emergency manual override that allows manual actuation in the event of a fault, e.g., during a power outage. The service socket (mini-USB) also allows the drives to be configured using the assistance tool.

Use :

The servomotors are not designed for continuous operation at the rated torque, but for short-term operation. The following intervals apply to the operating time (DF): at 100% load torque, the DF is 25%, which corresponds to a nominal operating mode S2 with a basic time of 4 minutes: operating time (DF) = 1 minute, followed by a break time (DP) of 3 minutes. At reduced load torque, the DF can be as high as 50% depending on the ambient conditions and application. The other operating modes are protected by l2t monitoring and temperature control as well as by an adjustable current limitation. Within the framework of this protection, a momentarily higher breakaway torque is permitted.

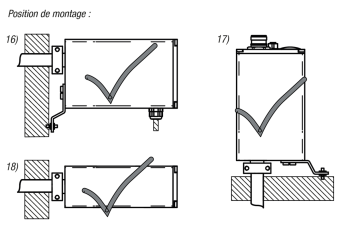

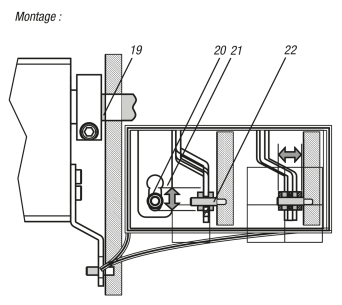

Assembly :

The servomotors can be mounted with the narrower side horizontally or vertically to the machine shaft. It is important that the driven shaft (fixed bearing) and the torque arm attachment point (loose bearing) are aligned to minimize mechanical stress on all components. When mounting horizontally, the servomotors must be mounted with the narrower side upwards. Mounting in a transverse position, i.e. with the wide side upwards, is only possible after careful assessment of the mounting conditions and approval from the manufacturer. The mounting concept provides for a fixed and a loose bearing. The fixed bearing absorbs the mass of the servomotor, which is mounted directly by adhesion to the machine shaft via a push-fit hollow shaft with a stop ring. The torque arm prevents the servomotor from rotating and acts as a loose bearing to compensate for any unbalanced movements at the driven shaft. Software available on request. Accessories: Stainless steel mounting kits for 85000-51 servomotors.

Français

Français