KONICA MINOLTA SENSING EUROPE BV

JUST Normlicht - Color Control LED Light Booth

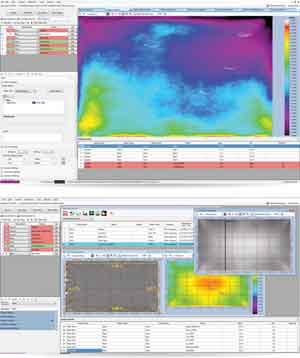

For visual color control in accordance with international standards In the Graphic Arts industry, an exact reproduction of the color of the original sample which can be a proof or a plastic material, fabric, a lacquered element, an interior part of automobile, etc. by the printing process is essential in order to meet the constraints of quality control while reducing costs. In addition to the colorimetric control carried out with a measuring instrument, visual verification is an important element, the most influential factor being the lighting. Incorrect illumination leads to wrong conclusions, causing complaints and thus increasing production costs. Capable of programming sources measured at any location with an appropriate instrument, this feature allows color to be judged under standard conditions as well as under special lighting conditions. Not only is metamerism detected in time, but also all color inconstancy effects are highlighted for any lighting conditions. JUST NORMLICHT has developed for the first time an LED light source that satisfies the requirements for color evaluation of all industries where color is a determining element. To control the properties of LEDs, JUST NORMLICHT has developed an advanced multi-level calibration procedure that calibrates each LED element and stores its spectral properties in its electronic module. This unique process is patented by JUST NORMLICHT Graphic Arts Printing

Illuminants D50 (with UV), D50 (without UV) and D65 in its “Basic” version with adjustment and control of the level of illumination Simulation of all standard illuminants: D50, D65, D75, A, CWF or TL84 etc. (with LED Control Professional software only) Control of UV emission for the detection of fluorescent agents (OBA) (with LED Control Professional software only) Selection of color temperature or chromatic coordinates (with LED Control Professional software only) Unique LED calibration method (patent pending)

Français

Français