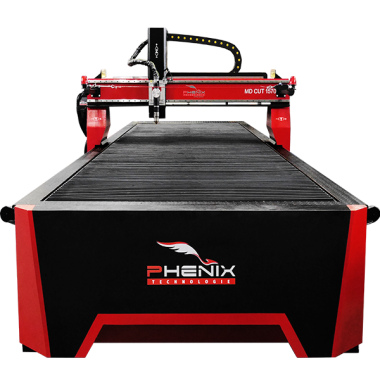

PHENIX TECHNOLOGIE

PRO JET 5 AXIS WATER JET CUTTING MACHINE

The 5-axis PHENIX TECHNOLOGIE hydro-abrasive cutting machines are equipped with the X5 Phénix Technologie system.

This system automatically compensates for jet lag and removes taper induced by jet taper. The X5 system has 2 rotary motors allowing the tilting of the head on the I and o axes. The cutting head can thus pivot in all directions, compensating for imperfections in the jet using complex mathematical models.

I axis: 1 Rotary axis (tilt)

O axis: 1 Rotary axis (orientation)

The 5X Phénix Technologie system equips the entire range of PRO JET machines, whatever the size of the cutting table and also the production of beveled parts.

The PRO JET 5-axis PHENIX TECHNOLOGIE water jet cutting machine is a mechanically welded structure, with lasting precision and a long service life. Designed specifically to minimize its wear due to the harsh environment of hydro-abrasive cutting. This is the guarantee of lasting precision and the assurance of low machine operating costs. With digital control.

The PRO JET 5-axis waterjet cutting system consists of:

- A very thick mechanically welded frame with precision machining of the guide surfaces

(DUAL GENTRY model - double X or Y axis).

- Access to the loading of the cutting table can be done by 2 of the sides of the machine.

- It can be equipped with 1 to 4 cutting heads and various tools (milling machine, drill...).

- Prismatic linear guide and ball screw transmission on all axes

- Motorized by 4 brushless motors with YASKAWA - OMRON incremental encoder.

Its axes are fully protected by protective slides against abrasive and its lubrication system

automatic facilitates its maintenance.

- Selection of quality materials and components (guide, ball screw shaft, nuts, sensors, cables, mechanical components

and electrical etc.) - CE standard.

-

Français

Français