Vigilant : Améliorer l’efficacité des éoliennes

Les éoliennes sont essentielles à la production d’énergie renouvelable, mais l’entretien de leurs systèmes complexes présente des défis uniques. Le Vigilant est une solution de maintenance conditionnelle à distance qui intègre l’analyse des ultrasons et des vibrations pour relever ces défis, offrant une approche simplifiée et efficace de la maintenance des éoliennes

L’importance de la maintenance prévisionnelle des éoliennes

Les éoliennes fonctionnent dans des conditions difficiles, souvent dans des endroits isolés et exposés à des conditions météorologiques extrêmes. Leurs composants – notamment les pales, les roulements principaux, les réducteurs et les générateurs – sont soumis à des contraintes permanentes. Les défaillances de ces systèmes peuvent entraîner des réparations coûteuses et des temps d’arrêt. La maintenance prédictive, qui s’appuie sur des technologies avancées telles que l’analyse des ultrasons et des vibrations, assure une détection précoce des défaillances, ce qui permet aux opérateurs de programmer les réparations de manière proactive plutôt que réactive.

Les éoliennes fonctionnent dans des conditions difficiles, souvent dans des endroits isolés et exposés à des conditions météorologiques extrêmes. Leurs composants – notamment les pales, les roulements principaux, les réducteurs et les générateurs – sont soumis à des contraintes permanentes. Les défaillances de ces systèmes peuvent entraîner des réparations coûteuses et des temps d’arrêt. La maintenance prédictive, qui s’appuie sur des technologies avancées telles que l’analyse des ultrasons et des vibrations, assure une détection précoce des défaillances, ce qui permet aux opérateurs de programmer les réparations de manière proactive plutôt que réactive.

Principaux défis liés à la maintenance des éoliennes :

- Hauteur et accessibilité

Les éoliennes dépassent souvent 80 mètres de hauteur, ce qui oblige les techniciens à grimper plusieurs fois par jour pour collecter des données. Ce processus prend du temps, est physiquement exigeant et présente des risques importants pour la sécurité. Vigilant élimine la nécessité d’escalades fréquentes en transmettant les données en temps réel à une station centrale de surveillance, ce qui améliore l’efficacité et la sécurité. - Des vitesses de rotation variables

Les différents composants d’une nacelle d’éolienne fonctionnent à des vitesses différentes. L’arbre principal tourne à une vitesse de 10 à 20 tours par minute, tandis que les roulements de la boîte de vitesses et du générateur tournent beaucoup plus vite. L’analyse traditionnelle des vibrations est moins efficace pour les pièces à faible vitesse, où les défauts à faible énergie peuvent passer inaperçus. La technologie à ultrasons du Vigilant excelle dans la détection des micro-frictions ou des impacts dans les roulements à faible vitesse, comblant ainsi cette lacune critique. - Coût de la maintenance non planifiée

Lorsque des composants critiques tombent en panne, les réparations nécessitent des machines lourdes telles que des grues et des équipes spécialisées. Ces interventions sont non seulement coûteuses, mais elles entraînent également des temps d’arrêt prolongés. La capacité de Vigilant à détecter les défauts à un stade précoce minimise ces interruptions, permettant des interventions planifiées et réduisant les coûts globaux.

- Hauteur et accessibilité

Les éoliennes dépassent souvent 80 mètres de hauteur, ce qui oblige les techniciens à grimper plusieurs fois par jour pour collecter des données. Ce processus prend du temps, est physiquement exigeant et présente des risques importants pour la sécurité. Vigilant élimine la nécessité d’escalades fréquentes en transmettant les données en temps réel à une station centrale de surveillance, ce qui améliore l’efficacité et la sécurité. - Des vitesses de rotation variables

Les différents composants d’une nacelle d’éolienne fonctionnent à des vitesses différentes. L’arbre principal tourne à une vitesse de 10 à 20 tours par minute, tandis que les roulements de la boîte de vitesses et du générateur tournent beaucoup plus vite. L’analyse traditionnelle des vibrations est moins efficace pour les pièces à faible vitesse, où les défauts à faible énergie peuvent passer inaperçus. La technologie à ultrasons du Vigilant excelle dans la détection des micro-frictions ou des impacts dans les roulements à faible vitesse, comblant ainsi cette lacune critique. - Coût de la maintenance non planifiée

Lorsque des composants critiques tombent en panne, les réparations nécessitent des machines lourdes telles que des grues et des équipes spécialisées. Ces interventions sont non seulement coûteuses, mais elles entraînent également des temps d’arrêt prolongés. La capacité de Vigilant à détecter les défauts à un stade précoce minimise ces interruptions, permettant des interventions planifiées et réduisant les coûts globaux.

Comment le Vigilant fonctionne dans la maintenance des éoliennes

Le Vigilant combine la précision des ultrasons avec les capacités à large spectre de l’analyse des vibrations, fournissant ainsi une image complète de la santé d’une éolienne.

- Vigilant prend en charge jusqu’à huit entrées de capteurs, collectant en permanence des données à partir de points critiques tels que le palier principal, les paliers planétaires du multiplicateur et les paliers du générateur. Le système détecte les anomalies telles que les frottements, les chocs ou les turbulences, qui indiquent des défaillances potentielles.

- Équipé d’une connectivité Wi-Fi, Ethernet ou cellulaire, Vigilant transmet les données en direct à une plateforme centrale. Les équipes de maintenance peuvent accéder à ces données à distance, ce qui réduit la nécessité d’interventions sur site et permet des réponses plus rapides.

- L’interface web intuitive de Vigilant rend l’analyse avancée des données accessible aux équipes de maintenance, quelle que soit leur expertise technique. Elle simplifie la détection des pannes et facilite la prise de décisions éclairées.

Le Vigilant combine la précision des ultrasons avec les capacités à large spectre de l’analyse des vibrations, fournissant ainsi une image complète de la santé d’une éolienne.

- Vigilant prend en charge jusqu’à huit entrées de capteurs, collectant en permanence des données à partir de points critiques tels que le palier principal, les paliers planétaires du multiplicateur et les paliers du générateur. Le système détecte les anomalies telles que les frottements, les chocs ou les turbulences, qui indiquent des défaillances potentielles.

- Équipé d’une connectivité Wi-Fi, Ethernet ou cellulaire, Vigilant transmet les données en direct à une plateforme centrale. Les équipes de maintenance peuvent accéder à ces données à distance, ce qui réduit la nécessité d’interventions sur site et permet des réponses plus rapides.

- L’interface web intuitive de Vigilant rend l’analyse avancée des données accessible aux équipes de maintenance, quelle que soit leur expertise technique. Elle simplifie la détection des pannes et facilite la prise de décisions éclairées.

A l’intérieur de la nacelle : le rôle du Vigilant dans la surveillance des composants clés

- Roulement principal à vitesse lente

La technologie des ultrasons est particulièrement efficace pour les composants à vitesse lente comme le roulement principal. En détectant des changements subtils dans les niveaux de frottement ou d’impact, le Vigilant fournit des avertissements précoces de défaillances potentielles. Par exemple, dans une installation récente, Vigilant a identifié un défaut de la bague extérieure d’un roulement à vitesse lente que les méthodes traditionnelles n’avaient pas détecté, ce qui a permis aux techniciens de résoudre le problème avant qu’il ne s’aggrave.

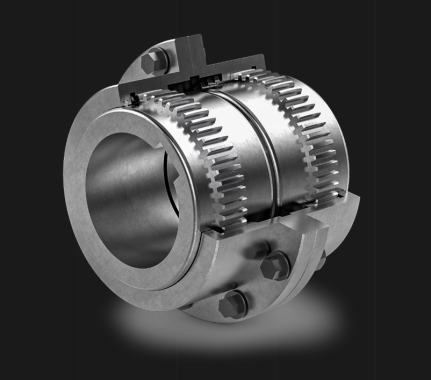

- Roulements du réducteur

Le réducteur est l’un des composants les plus critiques et les plus sujets aux défaillances dans une éolienne. Vigilant surveille ses roulements planétaires pour détecter les signes d’usure, de désalignement ou de problèmes de lubrification, ce qui permet d’intervenir à temps. - Roulements du générateur

Les roulements de générateurs à grande vitesse sont sensibles à l’usure et à la surchauffe. Les capacités de Vigilant en matière d’ultrasons et de vibrations permettent une évaluation complète de ces composants, garantissant ainsi un fonctionnement fiable. - Pales et accouplements

Les capteurs acoustiques du Vigilant détectent les anomalies telles que les fissures ou le relâchement des accouplements de pales, préservant ainsi l’intégrité structurelle de l’éolienne.

- Roulement principal à vitesse lente

La technologie des ultrasons est particulièrement efficace pour les composants à vitesse lente comme le roulement principal. En détectant des changements subtils dans les niveaux de frottement ou d’impact, le Vigilant fournit des avertissements précoces de défaillances potentielles. Par exemple, dans une installation récente, Vigilant a identifié un défaut de la bague extérieure d’un roulement à vitesse lente que les méthodes traditionnelles n’avaient pas détecté, ce qui a permis aux techniciens de résoudre le problème avant qu’il ne s’aggrave.

- Roulements du réducteur

Le réducteur est l’un des composants les plus critiques et les plus sujets aux défaillances dans une éolienne. Vigilant surveille ses roulements planétaires pour détecter les signes d’usure, de désalignement ou de problèmes de lubrification, ce qui permet d’intervenir à temps. - Roulements du générateur

Les roulements de générateurs à grande vitesse sont sensibles à l’usure et à la surchauffe. Les capacités de Vigilant en matière d’ultrasons et de vibrations permettent une évaluation complète de ces composants, garantissant ainsi un fonctionnement fiable. - Pales et accouplements

Les capteurs acoustiques du Vigilant détectent les anomalies telles que les fissures ou le relâchement des accouplements de pales, préservant ainsi l’intégrité structurelle de l’éolienne.

L’impact économique dans les parcs éoliens

Les éoliennes représentent des investissements importants et leur fiabilité est cruciale pour maintenir la rentabilité des parcs éoliens. Vigilant contribue à l’efficacité opérationnelle en :

- Réduisant les temps d’arrêt non planifiés

Grâce à la détection précoce des pannes, les opérateurs peuvent programmer les réparations pendant les périodes de faible vent, ce qui minimise les pertes de production d’énergie. - Prolongeant la durée de vie des composants

La maintenance proactive réduit l’usure, prolongeant la durée de vie des composants critiques et réduisant les coûts de remplacement. - Optimisation de l’allocation des ressources

La surveillance à distance réduit le besoin d’inspections sur site, libérant ainsi les équipes de maintenance pour qu’elles se concentrent sur les tâches prioritaires.

Les éoliennes représentent des investissements importants et leur fiabilité est cruciale pour maintenir la rentabilité des parcs éoliens. Vigilant contribue à l’efficacité opérationnelle en :

- Réduisant les temps d’arrêt non planifiés

Grâce à la détection précoce des pannes, les opérateurs peuvent programmer les réparations pendant les périodes de faible vent, ce qui minimise les pertes de production d’énergie. - Prolongeant la durée de vie des composants

La maintenance proactive réduit l’usure, prolongeant la durée de vie des composants critiques et réduisant les coûts de remplacement. - Optimisation de l’allocation des ressources

La surveillance à distance réduit le besoin d’inspections sur site, libérant ainsi les équipes de maintenance pour qu’elles se concentrent sur les tâches prioritaires.

Histoires de réussite : Applications réelles

Lors d’un déploiement remarquable, Vigilant a été installé sur une éolienne de 90 mètres dans un endroit éloigné. Le système surveillait en permanence sept points critiques, notamment le roulement principal à vitesse lente et les roulements de la boîte d’engrenages. En quelques jours, Vigilant a détecté un problème de lubrification dans le roulement principal et une défaillance imminente dans un roulement planétaire. Ces informations ont permis à l’équipe de maintenance de traiter les problèmes de manière proactive, évitant ainsi des temps d’arrêt et des réparations coûteux.

Lors d’un déploiement remarquable, Vigilant a été installé sur une éolienne de 90 mètres dans un endroit éloigné. Le système surveillait en permanence sept points critiques, notamment le roulement principal à vitesse lente et les roulements de la boîte d’engrenages. En quelques jours, Vigilant a détecté un problème de lubrification dans le roulement principal et une défaillance imminente dans un roulement planétaire. Ces informations ont permis à l’équipe de maintenance de traiter les problèmes de manière proactive, évitant ainsi des temps d’arrêt et des réparations coûteux.

Au-delà des éoliennes

Si l’efficacité du Vigilant dans la surveillance des éoliennes est indéniable, ses capacités s’étendent à d’autres actifs critiques dans les opérations industrielles. De la détection des décharges partielles dans les panneaux électriques à la surveillance de la cavitation dans les pompes, Vigilant s’adapte à une large gamme d’équipements, ce qui en fait un outil polyvalent pour la maintenance prédictive dans toutes les industries.

Si l’efficacité du Vigilant dans la surveillance des éoliennes est indéniable, ses capacités s’étendent à d’autres actifs critiques dans les opérations industrielles. De la détection des décharges partielles dans les panneaux électriques à la surveillance de la cavitation dans les pompes, Vigilant s’adapte à une large gamme d’équipements, ce qui en fait un outil polyvalent pour la maintenance prédictive dans toutes les industries.

Conclusion

Le 12 décembre 2024 par SDT ULTRASOUND SOLUTIONS

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français