Tokn is on tour

HELLER has launched the "Tokn on tour" campaign, in which the Tokn will be presented and showcased at numerous trade fairs and training events, including of course GI 2025. The story of a small teaching and learning machine that has everything a big one has!

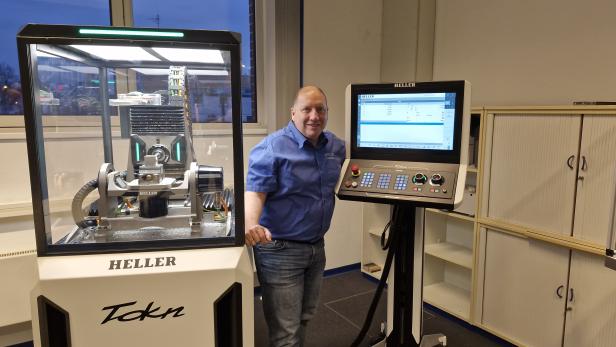

"We created the Tokn to give young people the opportunity to actively discover and shape the world of machine tools," explains Achim Hammley, project manager at HELLER Training. With the Tokn, apprentices assemble a complete miniature machine tool that is small and easy to handle. At the same time, the Tokn is used for CNC training. "As part of the CNC course, each of our apprentices learns how to use the machine to manufacture workpieces," continues Hammley.

For the record

In the 1980s, HELLER developed a completely new teaching and practical tool to improve the presentation and transfer of knowledge in CNC technology: the CNC ProfiTrainer, the predecessor of today's Tokn. To date, many young people have received professional training on the teaching tools in the HELLER training department. In the HELLER Academy training center, many HELLER users or its customers have been able to experience the advantages of the training system first-hand. In order to further improve identification, acceptance and operability, the Nürtingen-based company decided to give the space-saving mobile tool a modern look as part of a design facelift. In recognition of these efforts, the design was awarded the German Design Award 2025 in the category "Excellent Product Design – Industry" for its outstanding design quality. The tool is also used in the HELLER Academy for customer training. It allows customers to train their specialists in the optimal use of the brand's machines.

Big impact from a small machine

Unlike the original HELLER machine tool and other training systems, the Tokn is mobile and can be brought to the operator's workplace. The Tokn is designed, manufactured and commissioned by apprentices at Gebr. Heller Maschinenfabrik GmbH in Nürtingen, Germany. Linear axes move the tool, rotary axes move the workpieces. As with the machining centers in the current range, the control and control cabinet are equipped with real control components. The Tokn is equipped with the latest CNC control from Siemens, the Siemens SINUMERIK ONE, combined with an intuitive user interface that allows apprentices to work with high-performance machines right from the start. With this control generation, new possibilities such as the digital twin find their way into everyday working life. Programs can be tested and executed on the training tool in the same way as on the original machines. Even real machining of components is possible. All control functions of HELLER machines are integrated. Machine functions that cannot be executed are simulated via execution times in the control. The 5-axis machine also features integrated work area lighting and a height-adjustable external control panel. Using this CNC training system, skilled workers can be trained in a targeted, practical and concrete manner. The system trains them in the safe use of machining centres and enables them to carry out real machining operations on a fully configured machine. This concept helps to overcome fears and reservations, because people are often less intimidated by small things than by large originals.

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français