NORELEM

Steel or stainless steel positioning bushes with status sensor

The positioning sleeves provide a support point for the bolt-shaped operating and locking elements, into which they can engage securely and precisely.

Positioning sockets with status sensor have a variably adjustable sensor on the socket. This allows you to electronically check whether or not a bolt is in the positioning sleeve.

If several sockets are used, it can be determined in which the operating or locking element is located.

Use: Positioning sleeves combined with a status sensor enable actuation-dependent process control. They also ensure that the control or locking element is in the desired location.

For example when adjusting the format on packaging machines.

Material: Positioning sleeve in steel or stainless steel 1.4034.

Stainless steel sensor.

Brass clamping nut. Finish: Positioning socket:

hardened and burnished steel.

Hardened and polished stainless steel.

Polished sensor.

Nickel-plated clamping nut. Note: Suitable for 03099 supports.

Condition sensor and clamping nut delivered unassembled.

Maximum tightening torque of the clamping nut: 1.2 Nm. Technical data: Inductive sensor:

Output circuit: PNP NO contact

Operating voltage: 10 - 30 V DC

Operating current: <100 mA

Switching distance: 1mm

Switching frequency: <3500 Hz

Short circuit resistance: yes

Reverse polarity protection: yes

Protection index: IP 67

Connection type: PVC 2 m cable

Temperature range: -25°C - +70°C

Approval: CE, c-UL-us, EAC Assembly:

The sensor is fixed and adjusted axially to the socket using the clamping nut. The sensor is finally fixed by tightening the clamping nut.

The detailed procedure is described in the assembly instructions. Safety: Positioning sockets with status sensor are not intended to protect people. Drawing reference:

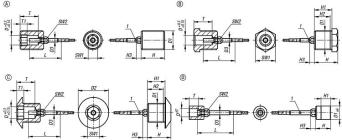

Form B: with thread and base

Form C: with thread and approach cone

Form D: smooth

1) LEDs

Français

Français