VISION ENGINEERING

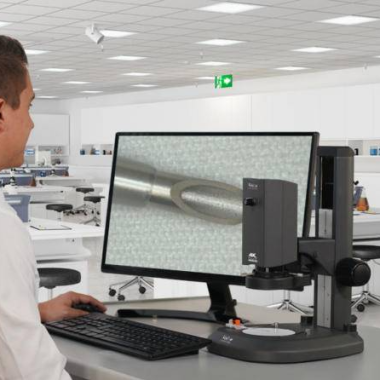

Hawk Duo

Automated high-precision video and optical measurement system

An ideal solution for method engineers, Hawk Duo gives you the reliability and precision of an optical measuring microscope – and the ease and repeatability of digital video measurement – in one robust system. It is a perfect tool for any precision engineering application that requires precise and automated measurements.

Effortless precision

Hawk Duo is equipped with a precision measuring stage with varied motion controls, and high magnification objectives to accurately measure even the smallest parts.

High productivity and throughput

The ability to inspect and measure simultaneously brings new levels of productivity to the work environment and rapid movement of the stage – even in manual mode – helps you complete measurement tasks more quickly. Hawk Duo can also run fast, programmable measurement routines with 3-axis CNC control.

Large objects

An expanded measuring capacity of 200mm x 150mm allows you to measure a wide range of parts and components, and the Hawk Duo's Z-axis travel is ideal for measuring larger objects.

2 in 1: the Hawk difference

Hawk Duo combines two measuring microscopes into one robust device, saving space and money. Use video measurement for routine work, where feature edges can be easily identified. For more difficult subjects, with very low contrast between subject and background, switch to optical metering.

For optimal performance, Hawk Duo uses Dynascope technology, unique to Vision Engineering, which makes it easier to measure subjects with difficult-to-see features at low contrast. You can now view and measure subjects with black-on-black or white-on-white characteristics and/or high levels of transparency using the Hawk Duo, easily and confidently.

The Dynascope advantage

Dynascope uses a rotating multi-lenticular disk with more than 3.5 million lenses arranged in a hexagonal shape on its surface. Each of these lenses, only a few microns in diameter, acts as an imaging surface.

By spinning the disk at high speed, the millions of individual light paths merge into a distortion-free, high-fidelity image that is viewed through an "eyepiece" with a diameter approximately 13 times larger than the narrow light paths that reach the eyes of the user with a conventional microscope. The large diameter of these exit rays means that users do not need to precisely align their eyes with the viewing lens to view the subject, allowing them to adopt a comfortable posture.

Easy-to-use M-Series measurement software

The Hawk Duo comes with industry-leading M Series metrology software for fast and accurate part inspections. Powerful yet easy to use, M Series software can perform simple or advanced measurement applications with minimal training. The intuitive user interface has a look and feel similar to apps on phones and tablets and is optimized for Windows 10 for easy report creation and printing.

Powerful productivity features

Part visualization similar to computer-aided design (CAD) allows for easy inspection of measured data. Many options exist: import/export in DXF format with digital layer-type comparison, automatic recognition of cable and thread diameters and complete point-to-point comparison to a theoretical profile

Lighting Options

Because everyone has different needs, we've ensured that Hawk Duo can be custom configured with a wide range of lighting options, including a ring light with programmable LED for even, shadow-free surface lighting , axial lighting for inspection of blind holes and adjustable under-stage lighting for translucent parts.

| Measuring capacity | |||||||||||

| 200mm x 150mm x 244mm | |||||||||||

8″ x 4″ x 9.6″

|

Français

Français