NORELEM

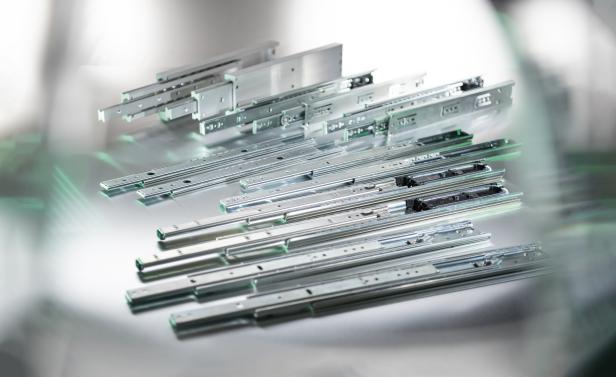

Telescopic slides

Linear guides are essential in any industrial environment, helping to move equipment and objects along the production line. Marcus Schneck, CEO of norelem, explains what to consider when choosing a linear guide.

Culturally, the term "linear" has acquired an unfair reputation over the past few decades. To say that something is linear is to suggest that there is no complexity; it is simple, straightforward, easy, there are no gaps, no unknown parameters where one can make mistakes.

Of course, when it comes to manufacturing, this is exactly why linearity is so crucial. In demanding applications such as factory automation, the danger is having systems or processes that aren’t linear enough. Near-straight motion isn’t enough: production lines depend on machines that will move safely along a predetermined axis, over and over again.

To achieve this quality of linear transfer, design engineers use linear guides. In principle, this is the same technology that allows people around the world to open clothes drawers reliably and smoothly, day after day. Yet the stakes are considerably higher in an industrial environment. A linear guide must be strong and frictionless. It must maintain its performance over thousands, if not millions, of repeated movements, and it must withstand the stresses without deforming.

Which linear guide is right for you?

Choosing the right linear guide is not easy, and it is important to do it correctly. There are two main types of linear guide systems, each with its own characteristics.

Slide guides are linear guides in which the individual guide elements are not separated by rolling elements. Roller guides, on the other hand, are based on a rotating mechanism, whereby the slides include rollers or ball bearings that are rotated between two moving elements.

In all cases, the end result is the same: the linear block moves forward and backward along the plane on which the rail is positioned.

Slide guide

Linear guide systems with slides include the norelem dovetail slide, which prevents the guide element from lifting during rotational movements. The extended contact of the sliding surfaces makes dovetail slides well suited for absorbing and damping shocks and vibrations.

Telescopic slides are another option – and norelem now offers 33 types, designs and sizes, allowing movements for payloads from 10 kg to 450 kg. When putting together this comprehensive range, we have focused on reducing friction, noise and maintenance requirements.

The slides are made of standard steel but are also available in stainless steel or aluminium. Stainless steel is corrosion-resistant and guarantees maximum hygiene: perfect for medical technology. In comparison, aluminium is lightweight, making it ideal for applications such as aviation, where every gram counts.

Roller guide

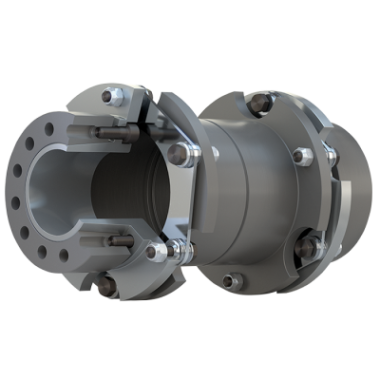

A rolling element retainer (such as a roller chain) helps control the rolling element and ensures that the guide operates as quietly as possible. Roller guides include profiled guide rails and linear ball bearings.

norelem roller guide systems include guide rails with a length of up to 4080 mm and in compact and robust versions of 20 mm, 30 mm and 45 mm. Depending on the size and dimensions, the roller slide systems can withstand static loads of up to 5,500 N and dynamic loads of up to 12,280 N, depending on the size and dimensions.

The combination of fixed and floating bearing rails prevents annoying tilting and unnecessary wear of the roller guide systems, as the carriage can be made play-free by simply adjusting the central roller to the desired tension in the rail. This ensures precise operation, with the permanently lubricated roller bearing ensuring maintenance-free operation.

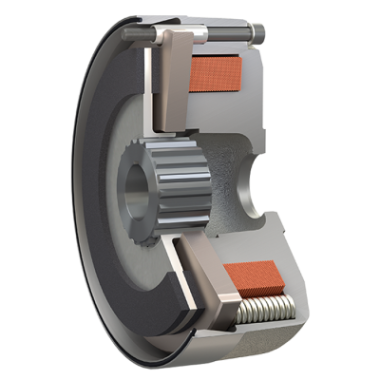

Another type of roller guide is those equipped with recirculating ball elements. The rolling elements recirculate inside the linear block and move with it and not separately, like the tracks of a tank.

Other points to consider

As a general rule, a good quality guide depends on its shape, positioning accuracy and the absence of friction. This means that when specifying and dimensioning a linear guide system, you can take a logical approach.

Once you have clearly defined the most important parameters required for your application, you can probably determine whether a slide or roller guide is the best system to use.

Based on this decision, you can then refine the selection based on specific variables, such as speed, load, material, maintenance, etc.

Choosing linear systems from norelem

At norelem, we have extensive experience in helping our customers choose the right linear guide system. Our linear guides are used in industries as diverse as semiconductor manufacturing, robotics, packaging and medical technology, although naturally the main area of application is factory automation.

When necessary, we are happy to advise customers on the right features for positioning, handling, lifting or rotating production elements. This means that our linear guide systems can be assembled according to the customer's specific application.

In short, a linear guide is a simple device that does a simple job well. The next time someone complains that something is too linear, take linear guides as an example and remind them that sometimes, simple is exactly what you need.

Français

Français