BECKER FRANCE SARL

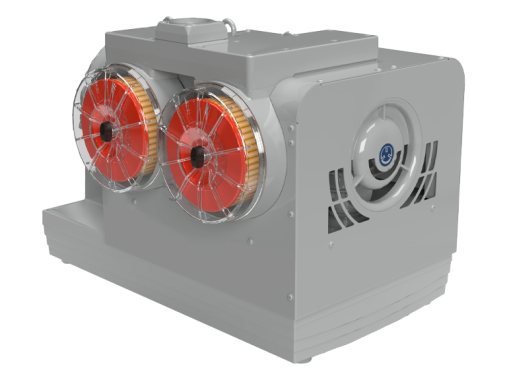

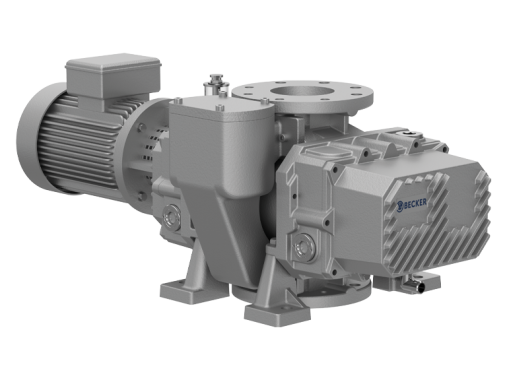

Systems & Power Plants

Centralized systems consist of grouping all the pumps and compressors present on the production machines, in a single separate room (control room, basement, etc.). The units are connected to the production machines by pipes.

Centralized systems provide your machines with vacuum and blowing air on demand, which means energy savings. Noise levels are significantly reduced in employee work areas. Each pneumatic supply in a centralized system is equipped with its own frequency converter. This means that the pneumatic requirements of each production machine can be continuously adapted for a given operating point. On average, frequency-controlled units operate at a relative speed of around 65%. Overall, this results in significant energy savings compared to separate units and devices without speed control.

Français

Français