NORELEM

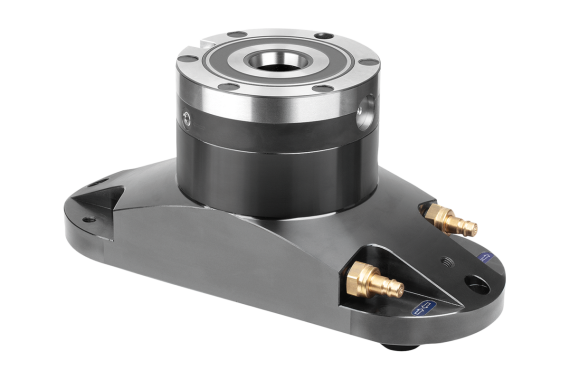

Extensions for UNILOCK ESM 138-C clamping modules

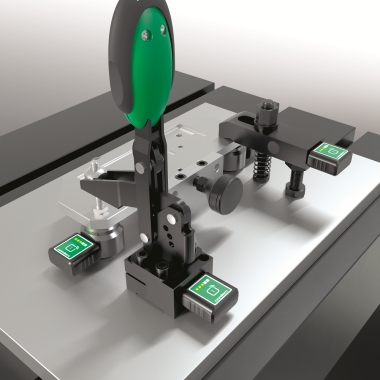

The module risers can be attached to the UNILOCK clamping modules via two zero-point exchange interfaces. This installation is possible with a center distance of 200 mm between the two clamping modules. The module risers ensure fast and reproducible replacement of fixtures and workpieces in the machine room. These clamping systems provide optimal access to the workpieces thanks to raised or inclined exchange interfaces. The use of the module risers also enables central alignment in the machine room.

They allow machining on several faces by determining the clamping position in an oriented manner.

Clamping module made of case-hardened steel.

The release is pneumatic.

Even in the event of pressure drops or fluctuations in the compressed air supply, the tensile force is fully maintained.

All clamping modules have a turbo function as standard. A brief air pulse at the "Turbo" air connection significantly increases the tensile force achieved by the springs. The clamping modules are therefore also very suitable for heavy-duty machining.

It is recommended to use the turbo function to obtain maximum traction force.

The following clamping forces are possible by combining UNILOCK clamping pins with M10, M12 and M16 fixing screws:

- Clamping force (M10) 35,000 N

- Clamping force (M12) 50,000 N

- Clamping force (M16) 75,000 N

Clamping force with CHC screw DIN EN ISO 4762-12.9

The clamping pins should only be clamped in the clamping module in conjunction with a mounted replacement unit.

A common clamping spindle size for all clamping modules and compatibility with the 5-axis modular clamping system 80 guarantee a wide range of applications.

- System pressure: 6 bars, lubricated air.

- Repeat accuracy ≤0.005 mm.

- Optional connection for purified air.

- Repeat accuracy ≤ 0.005 mm.

- Positioning using short cones.

- High tensile forces.

- Optimization of equipment times.

Français

Français