NORELEM

Connected positioning system

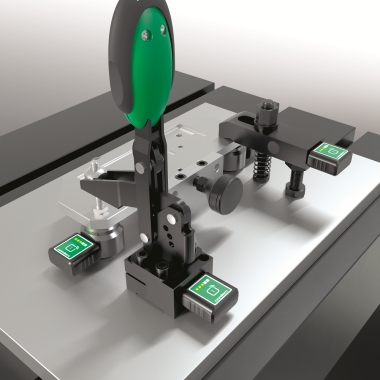

With the rise of the Internet of Things (IoT) and Industry 4.0, modern workshops are rapidly transforming into smart, connected environments.

Take advantage of this technology to easily check tightening and positioning before machining, thanks to ergonomic and intuitive implementation.

norelem connected products have many advantages:

• Intuitive configuration : Connected products have simplified settings, allowing intuitive assembly. This optimizes installation speed, reduces errors and makes it user-friendly, even for uninitiated operators.

• Optimized quality : Connected products ensure that each part is correctly positioned and held, reducing scrap and costs associated with re-machining.

• Wireless operation : Components install and connect without any wiring.

• Resistance to cooling lubricants : Connected products have an IP64 protection rating, suitable for machining with cooling.

• Increased productivity : By reducing machining errors, shops can speed up production without impacting quality.

• Cost reduction : Wasted materials, wasted time. Connected products minimize these errors.

• Proactive maintenance : These products can also report wear, anomalies or any maintenance needs, allowing potential problems to be anticipated.

• Easy training and support : Connected products can be linked to a computer system providing real-time feedback to operators throughout the machining process.

Verification of tightening and positioning represents a major advance in the world of machining. It offers superior quality assurance, but also increased efficiency, reduced costs and better overall workshop management. In an industry where precision and efficiency are crucial, these products represent the future.

In order to integrate products connected to machines and installations, norelem offers you a gateway. The connection between the gateway and the machine controller allows the actuation status of the connected products to be displayed, checked and evaluated.

Quickly view the status of your sensors using the norelem application by monitoring a single connected product or an entire gateway.

On a tablet or smart phone, check your machining setup before, during and after machining!

The range of connected products includes

-

A universal transmitter : The association of universal transmitters with connected products allows visual, intuitive and rapid reading of the status of the sensors. It is also possible to wirelessly transmit the status of the sensors via Bluetooth.

-

Smooth feet with part presence sensor : The smooth feet with part presence sensor allow control of the part positioning process. They can also be used as stops with feedback on the final position. 0.2mm switching distance. Ensure reliable positioning of the part on the machining device.

-

Force sensors for clamps : Force sensors for clamps allow control of the workpiece clamping process. Ensure perfect clamping of the part with increased repeatability.

-

Flanges with force sensor: Flanges equipped with a force sensor allow control of the workpiece clamping process. Switching value: ±10% of setpoint. Ensure perfect clamping of the part with increased repeatability.

Français

Français