V-OPTICS

QualiLENS®100 & 150

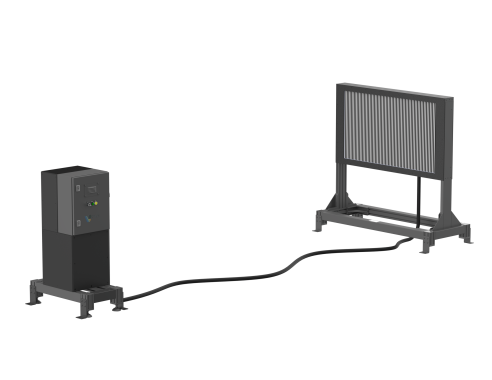

The QualiLENS®100 and 150 systems are designed to improve cosmetic inspection of intraocular lenses (IOLs) by automating defect detection, a critical requirement for IOL manufacturers. Suitable for production environments, they integrate seamlessly into manufacturing lines.

The QualiLENS®100 is an efficient solution for individual lens inspection, while the QualiLENS®150 enables batch inspection on trays.

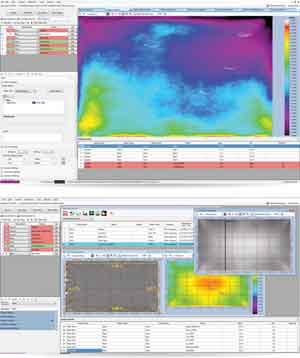

These systems go beyond simple defect visualization by not only identifying but also automatically classifying and sorting manufacturing defects. The innovative approach of our systems lies in the combination of optical technologies and software engineering. The system identifies and classifies defects such as machining marks, chips, scratches and chipped edges with high precision. The digital evaluation ensures repeatable and objective controls.

Increased productivity is achieved through faster and smoother inspections, optimization of quality costs and elimination of overquality costs – only proven non-conformities are rejected.

Français

Français