Implementing Ultrasound Technology for Predictive Maintenance at ADM Razgrad

In a strategic move to enhance operational efficiency and minimize downtime, ADM Razgrad, a food processing facility located in Bulgaria, undertook the implementation of a predictive maintenance program centered around improving the reliability of its critical machinery.

This initiative leveraged ultrasound technology, yielding significant benefits in preventing equipment failures, reducing costs, and ensuring the plant’s uninterrupted operation.

The journey began with a comprehensive reliability assessment across all machines in the plant. This assessment was crucial to identify which equipment was most critical to the production lines and overall plant operations. By pinpointing the key machinery and understanding potential problems, we were able to prioritize our maintenance efforts effectively.

Following the identification of critical machines, they conducted a thorough Reliability-Centered Maintenance (RCM) and Failure Modes, Effects, and Criticality Analysis (FMECA). The analysis revealed that the most vulnerable components across the critical machines were their bearings. Given the significant role these bearings play in machine operation, they required close monitoring to prevent costly failures and downtime.

For their slow-rotating equipment, ultrasound technology appeared to be the ideal solution for condition monitoring. They chose ultrasound due to its reliability in monitoring bearings with rotational speeds below 120 rpm. Additionally, this technology proved effective in detecting compressed air and vacuum leaks, which could otherwise lead to energy losses and operational inefficiencies.

To support the implementation of this technology, they invested in an ultrasound tool from SDT Ultrasound Solutions, the SDT270, and installed the accompanying software Ultranalysis Suite 3 (UAS3). A comprehensive database was established, and they developed a condition monitoring program featuring monthly routes to inspect bearing conditions and detect leaks. This systematic approach ensured they maintained a clear understanding of their equipment’s health, enabling proactive measures to be taken when necessary.

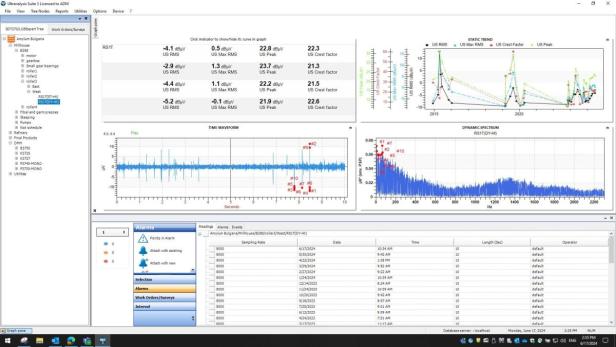

Image showing the UAS3 interface.

Building on their previous experience with vibration monitoring, they smoothly integrated the ultrasound condition monitoring program. This transition allowed them to capitalize on their existing knowledge while implementing the new technology. Early in the program, they detected damage in the support roller bearing of one of their dryers. Thanks to the early detection provided by ultrasound, they were able to continue monitoring the bearing and plan the necessary repair months in advance, preventing an unexpected shutdown.

Image showing the routes in UAS3.

Image showing the detected bearing problem.

Precise monitoring of each activity was crucial to measuring the effectiveness of the predictive maintenance program. Through diligent monitoring efforts, they successfully prevented several major failures in their slow-rotating bearings. This proactive approach saved the company from significant repair costs and avoided prolonged downtime, which would have severely impacted production.

Image showing the monitoring outcomes and data trends

For every failure they prevent, they calculate the associated cost savings and present these findings to plant management. This transparent reporting not only highlights the value of the predictive maintenance program but also ensures that the financial benefits are clearly understood and appreciated throughout the organization.

As the program matured, they developed a system for logging all detected issues and estimating the timeline for necessary repairs. By tracking the costs of avoided failures, they accurately calculated the return on investment (ROI) from the ultrasound technology. Once the investment was recouped, this success was reported to management, showcasing the financial prudence of the program.

Each year, they will compile a report detailing all the losses prevented by the predictive maintenance program. This cumulative benefit is measured against a defined gap value, and once this threshold is reached, it is celebrated as a significant achievement. Continuous reporting of these successes will reinforce the program’s value and establish it as an integral part of their maintenance strategy.

Conclusion

The implementation of ultrasound technology at ADM Razgrad has been a resounding success. By focusing on critical machinery, developing a robust monitoring program, and consistently reporting their achievements, they have not only improved the reliability of our equipment but also significantly reduced operational costs. This success story underscores the power of predictive maintenance and the importance of investing in the right technology to safeguard the future of their operations.

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français