NORELEM

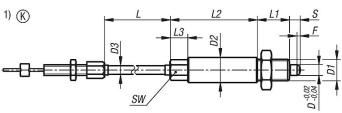

Stainless steel indexing pins with remote control

Indexing fingers are used when it is necessary to prevent movement of the stopping position due to transverse forces.

For example for length and height locking as well as position locking in machinery, furniture and special vehicle construction.

Indexing plungers with remote control are used when inaccessible spaces make handling difficult or when remote control is required for ergonomic and safety reasons.

The coupling between the indexing finger and the operator side is carried out with a Bowden cable. The combination of the indexing finger and the control element forms a complete system which can be suitable for many applications. If disengaging is to be effected permanently and retraction of the stop finger is to be avoided, the form D actuating element with locking function should be used.

As an alternative to the control element, the supplied screw connection (Ø5 x 7 mm) is used to integrate a separate control element into the system.

Bowden cable is available in different lengths.

To ensure a perfect fit for the respective application, the Bowden cable can be shortened accordingly during assembly.

A selection of appropriate materials and coatings helps ensure protection against corrosion. The Bowden cable and cable jacket can be easily replaced if necessary.

Material: Index pin:

Threaded body in stainless steel 1.4305.

Stop pin in stainless steel 1.4034.

Control element in stainless steel 1.4305.

Thermoplastic operating knob.

Thermoplastic capsule.

Stainless steel cable 1.4401.

Steel wire cable jacket with interior and exterior plastic coating.

Brass end caps, set screws and screw connections. Finish: Indexing pin hardened, ground and polished.

Black Bowden cable jacket.

Dark gray thermoplastic operating button.

Ordering notes: The indexing fingers with remote control and the operating element must be ordered separately. Note: When installing Bowden cables, the following points should be considered:

the length of the free end of the cable may vary depending on the installation angle, bend radius and load. Therefore, the length of the counterstop (cable sheath) must be adjusted using the stop screw provided after installing the Bowden cable. The pretension of the Bowden cable system can be adjusted at the same time using the set screw.

During installation, particular care must be taken to respect the minimum curvature radius, in this case R = 65 mm. A spoke that is too tight can lead to increased wear and increased friction.

It is also important to avoid temporarily going below the minimum bending radius during assembly so as not to damage the cable sheath. Furthermore, the sheath is only designed to absorb pressure forces. If it is too tight, the inner spiral is stretched and permanently damaged. Accessories: Nuts 07212.

Indexing pin supports 03099.

Spacers 03089.

Positioning sockets 03099-50.

Control item 03096-10-12420.

Français

Français