URETEK France

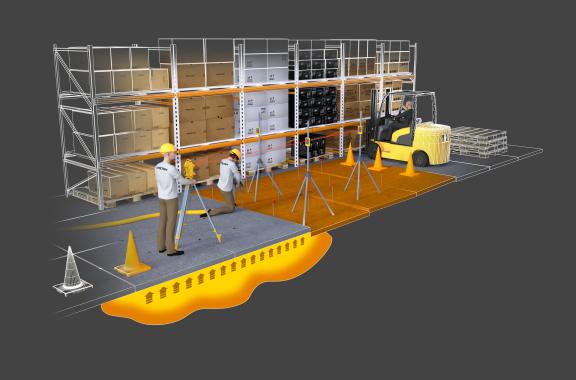

Lifting of slabs

Stop paving subsidence and slab flapping

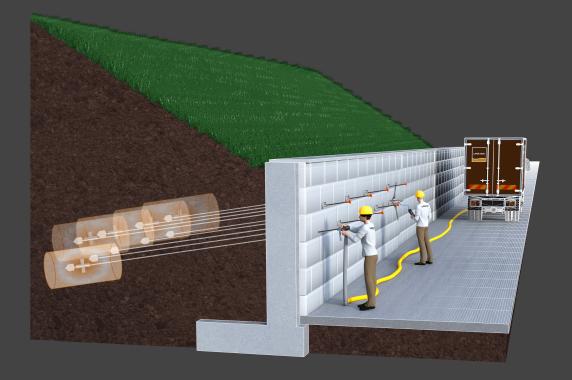

The URETEK® process makes it possible to counter the problems of subsidence and scuffing of slabs by injecting an exclusive expansive resin into the base layer of the slab. Its expansion and hardening compact the base course and then raise the paving.

Multiple apps…

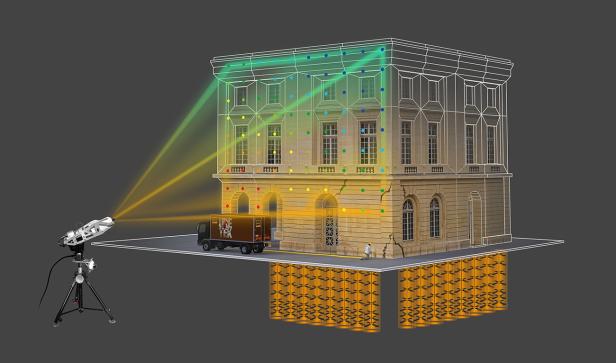

The solution can be applied to all types of buildings built on land and faced with subsidence of paving for:

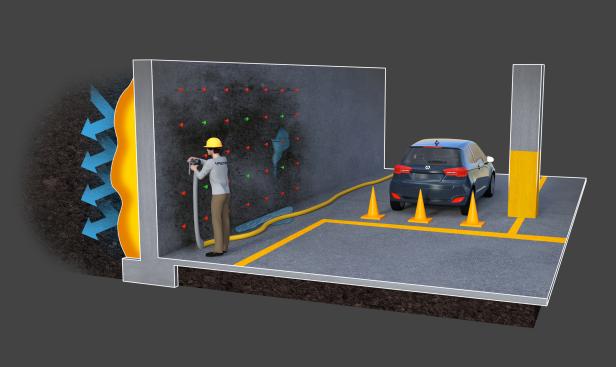

- Leveling subsidence in pavements, roads, tracks, etc.

- Renovate buildings on unstable ground as a preventive action

- Stabilize and stop slab flapping or rattling problems

- Increase the lowering of the load in the event of requalification of zones

…for different areas

The process is perfectly suited to sagging industrial floors , commercial surfaces and storage warehouses , roads, roads and tolls or airport and railway structures.

A quick response

After a phase of careful inspection and identification of the buried networks, the URETEK® intervention team drills holes in the area to be treated according to a precise mesh to insert the injection tubes. The exclusive expansive resin is then injected to penetrate under the paving and fill the voids on the underside. Almost immediately, it expands and then solidifies to compact the base layer, and raise the sagging paving if necessary.

The operation takes place under a permanent laser level control to check and control the evolution of the lifting of the sagging slabs.

The strength of URETEK ® resin

The expansive resin is injected into the base layer of the slab in the liquid state, which allows it to diffuse and penetrate into all the voids present under the slab. It is then very quickly that it polymerizes, solidifies and expands.

It is the expansion pressure of the resin that allows the lifting of the paving and heavy loads and not the pressure of its injection.

An immediate result, your activity preserved

The result on each treated area is instantaneous. If necessary, the sagging slabs can be raised up to 30 cm in order to secure the area and restore the initial flatness of the ground.

The area thus treated is totally consolidated in a definitive way. It is then reusable without delay .

The progressive reuse of the areas already injected makes it possible to keep a site open and to continue the activity.

The advantages of this solution

- Very fast implementation

- No business interruption or relocation

- Immediate reuse of treated surfaces

- Raising the paving by several centimeters

- Accuracy to 10ths of a mm

- Clean and dust-free site

Français

Français