SYNERGYS TECHNOLOGIES

LEAKSHOOTER® V2+ IR

The LEAKSHOOTER® becomes the double ally of the maintenance technician, first in the search for leaks of compressed air, pressurized gas and vacuum and then in the remote detection of any overheating or abnormal temperature.

The LEAKSHOOTER® V2+ IR is a complete tool that first allows the optimization of compressed air and vacuum and pressurized gas networks and today also also thanks to an on-board thermal camera, 160 x 120 pixels, - 10°C >+400°C, with sliders Min. Max. Central, to locate an electrical malfunction, mechanical defect or metallic corrosion.

The LEAKSHOOTER® V2+ IR allows considerable energy savings according to the ATEE (Association Technique Energie Environnement)

https://www.ademe.fr/sites/default/files/assets/documents/8246-guide-air-compresse-atee.pdf

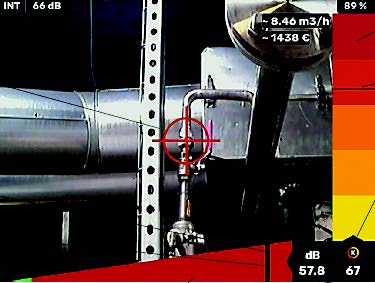

Example: cost of a leak in the case of an opening

with a section equivalent to a 3 mm diameter hole in a

network at 7 bar relative:

- the loss of flow is of the order of 12.1 l/s or 43.8 m³/h;

- in regulation, it generally takes about 0.16 kW to

obtain 1 m³/h at 7 bar;

- the power required to compensate for the leak is therefore

7kW;

- hence, with an average rate of 6,000 hours/year and one kilowatt hour at €0.07 excluding tax, the annual consumption of 42,000

kWh corresponds to an expenditure of €2,940 excluding tax.

Conclusion: a single leak through a 3 mm diameter hole costs approximately €3,000 excluding tax per year.

The LEAKSHOOTER V2+ IR with its on-board thermal camera also allows the reduction of risks and malfunctions, in process controls, it detects and immediately locates an anomaly, it allows a pre-diagnosis on a mechanical or even fire risk.

This maintenance prevents costly production stoppages.

Maintenance of installations, vacuum compressed air networks, machines and electrical substationsDetection of compressed air leaks, gases under vacuum pressure and infrared thermography

Français

Français