SYNERGYS TECHNOLOGIES

VSHOOTER®+ Vibration analyzer

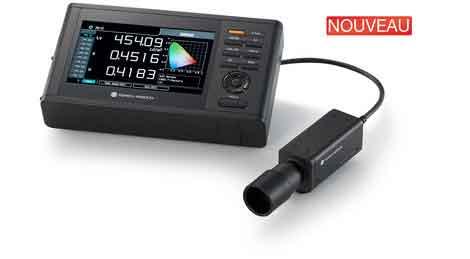

The VSHOOTER®+ automatic analyzer is capable of quickly finding vibration defects in rotating machines such as electric motors, pumps, fans, rolling bearings or even machine tool spindles.

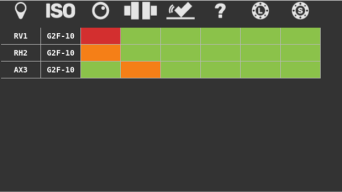

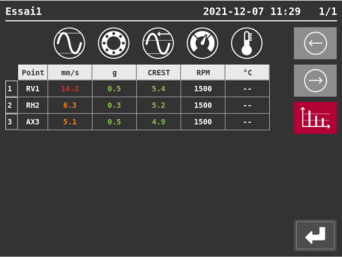

With its MCP (Machine Condition Photo) program, the VSHOOTER®+ automatically measures and diagnoses excessive machine vibrations caused by:

Unbalance, misalignment, loosening/foundation or even a lubrication problem and shocks on the bearings.

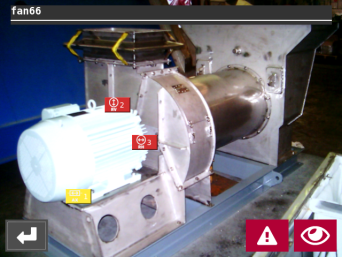

Thanks to its integrated camera, the VSHOOTER®+ creates an MCP from the photo of the machine. On the MCP “machine condition picture” the main faults detected will be displayed.

Finally, the VSHOOTER+® can also focus only on the severity of the Unbalance or Misalignment fault with the BALISHOOTER® function.

Unbalance or misalignment problems are responsible for 70% of vibration problems on rotating machines.

SYNERGYS TECHNOLOGIES has developed a program dedicated to this type of malfunction:

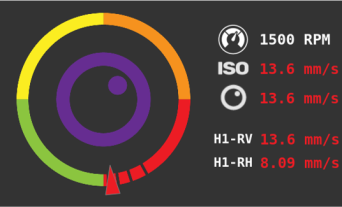

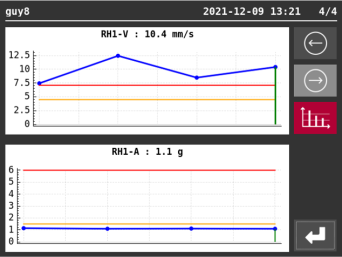

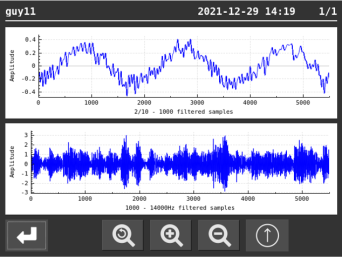

The BALI SHOOTER® program allows automatic analysis (v (mm/s) FFT spectrum) exclusively dedicated to unbalances or misalignments.

Neglecting Unbalance & Misalignment can be catastrophic: BREAKAGE – DROP IN MTBF – BEARING PROBLEMS – LOSS OF PRODUCTION – SEALING PROBLEMS…

Unbalance & Misalignment, on direct couplings can be very easily repaired through balancing and alignment measures.

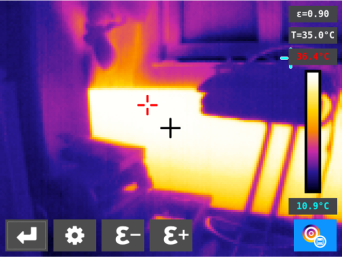

The VSHOOTER+® also includes an infrared thermal camera (160x120 pixels FLIR LEPTON) with emissivity adjustment, 1x central cursor, 1x Auto Max cursor, 1x Auto Min cursor.

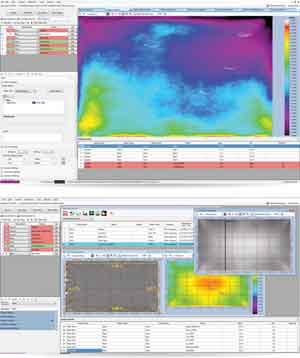

All measurements taken can be stored and exported to PC (via USB) to produce a report (PDF-HTML, etc.).

Français

Français