Control / Measure / Industrial vision

Automation of production equipment also requires the setting up of a good control, measurement and vision system.

A few definitions

Industrial control consists in using equipment and software to monitor the operation of machinery. The system can also be used to monitor and automatically manage industrial processes. An industrial control and automatic regulation (CIRA) technician will subsequently deal with the malfunctions observed.

Industrial measurement or industrial metrology is an essential process which aims to certify the compliance of a product and monitor its wear during use. It is part of a quality process procedure and must meet industrial standards.

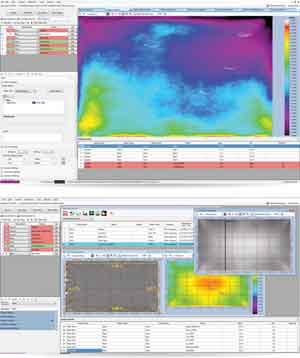

Industrial vision is a set of technologies and methods used to determine whether a product meets the defined standards. This requires a vision system consisting of a lighting system and an industry camera.

Categories of control, measurement and vision systems

Setting up a good vision control system is the best way of guaranteeing the quality of the products supplied by industries. And to successfully implement this process, various measurement and analysis devices need to be used.

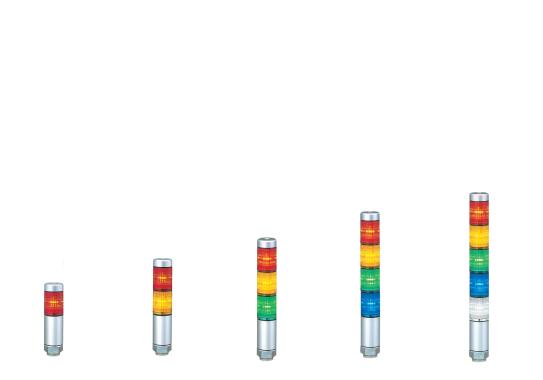

This means using multi-channel meters, barcode scanners, wireless scanners, labels and badges, as well as sensors, flowmeters, particle counters, industrial thermometers and ultrasonic rangefinders.

Manufacturers offer 2D vision systems and 3D industrial vision systems which are much more sophisticated and more effective. Lastly, we should also mention dosing devices such as automatic dosers and robotic tables.

Our referenced suppliers

Wago Contact, Synergys Technologies, Sika France, Wimesure, JLH Mesure, ENVEA, CIPAM, ERI SAS, PAMAS and Systolic.

Français

Français