NORELEM

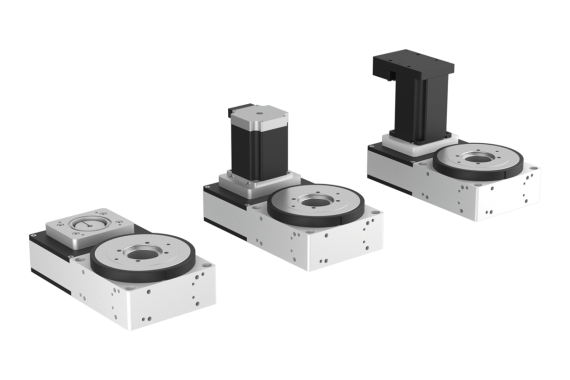

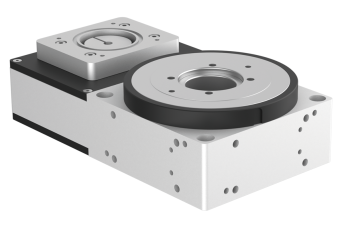

Circular positioning tables with toothed belt drive

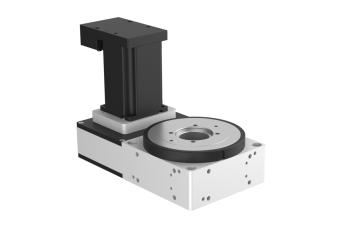

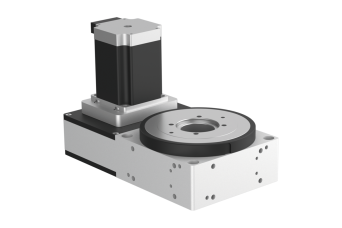

Circular positioning tables with toothed belt drive are suitable for precise and fast positioning of workpieces. The rotary table of the motorized rotary table is driven by a stepper motor and a toothed belt drive. Thanks to its square shape, the rotary axis can be integrated in a wide variety of machine types.

Pneumatic and electrical lines can be passed through the large hole in the hollow shaft without interfering with the operation of the rotary table. This hole also has an H7 adjustment for centering the turned part. The adjustable positioning ring allows the rotation reference point to be freely defined in relation to the position of the mounted component.

Support is provided by a crossed roller bearing.

Possibility to mount proximity sensors with the optional sensor bracket (21085-02-901).

We offer the corresponding programming software for download.

The stepper motor, with its resolution of 200 steps per revolution, allows a theoretical positioning accuracy of 0.005 mm in each direction. The absolute positioning accuracy in each direction is 0.01 mm. The system can operate with a duty cycle of 100%.

Matter :

Aluminum case.

Stainless steel turntable and hollow shaft.

Finishing :

Anodized aluminum.

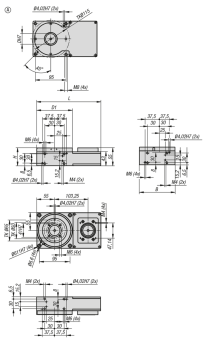

Technical data: 21085-10*:

Transmission ratio: 2:1

Inversion game: <0.2°

Turntable concentricity: <0.02 mm

Max. input speed: 600 rpm

Max. duty cycle: 100%

Required input torque: 0.13 Nm

Rigidity: see diagram

Rotation: 360°, endless

Operating temperature: from +10 °C to +60 °C

Yield η: 0.85

Français

Français