DAVOC

Initial and/or Periodic General Lifeline Checks

Initial verification PPE fall arrest and collective protection

Fall protection equipment

Our experts accompany you from the study to the tests in the individual and collective fall protection equipment:

- In the Control of the DOE , of the Instructions for use , of the Periodic General Verification Sheets , of the recommendations for personal protection PPE Fall Protection (according to standard EN 795-2012)

- In the Verification of compliance with assembly Manufacturer of access systems (stairs / crinoline ladders / step ladders / ...), collective protection (Guardrails / Walkways, ...) as well as anchor points / life lines (rail or cable / vertical or horizontal) against falling from a height

- In Tests and resistance tests of the host structure , fixings , special interfaces (posts or plates) , crimping , tightening , cable tension , welding ... (according to Standard EN 795-2012)

- In the Analysis of technical justifications : calculation note for interfaces or metal construction (FOLLOWING Eurocode 3), validation of the host structure (support), Executed Work File, ...

- In the Functional test which may require partial dismantling and must be carried out by qualified technicians technical analyzes of the offers of the companies consulted

Periodic general check (Anchors / Lifelines / Fall arrest harnesses / …)

Lifeline control

Lifeline analysis, operation and control

In the world of work, especially in the construction industry, regulations increasingly require the use of fall protection solutions and protective equipment such as safety harnesses. Among the existing responses to this occupational health concern, lifelines, among other things, allow workers to circulate at height in a safe manner. Davoc checks its technical systems in order to optimize their safety, to check that they are in compliance with the standard and to facilitate the work of the personal users of these lifelines.

The reduction of cases of falls as a priority

Against the risk of falls from height, the control of the lifeline is an essential point for working in complete safety . It is she who can be the only fall arrest in progress thanks to her anchoring devices.

The work of our teams

Our offices check the individual and collective fall protection equipment, from the lifeline to the harnesses and advise you in the choice of the available options:

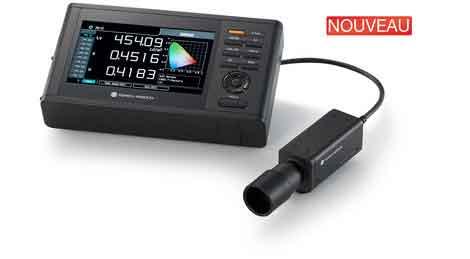

- Examination of the state of conservation / individual protection, ... by photos and videos, of the adjustments of the lifeline, tension of the cable and readjustment on site if necessary

- Functional test that may require partial disassembly and must be carried out by qualified technicians

- Tests of bindings, hooks, carabiners, fixed anchors if necessary

CONTROL AND TEST

- Commissioning of the facilities.

- Periodic General Checks.

- Functional checks.

- Verification of mandatory documentary elements: DOE, justification of elements and reception structure by Calculation Note, user instructions, operating procedure, etc., as well as mandatory displays.

- (Visual) checks of the various elements/components (deformations, corrosion, sizing, welds, missing elements, etc.).

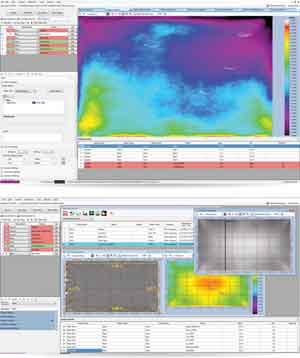

- Validation of the reception structure by extractometer.

- Structural anchor tests at 500 daN following recommendation R430/SP110 (excluding non-calculable host structures).

- Checking tightening torques on bolted assemblies (following manufacturer/installer recommendations).

- Crimp testing.

- Non-destructive testing of bollards (interfaces).

- Non-destructive testing of bodyguard samples on cladding.

- Check cable tension (following manufacturer/installer recommendations).

Français

Français