Detecting Compressed Air and Gas Leaks Using the SDT340: A Cost-Saving Solution for Industrial Efficiency

Compressed air is essential to industrial operations, driving pneumatic tools, automation systems, and various processes across many sectors.

Its reliability, ease of use, and adaptability make it the fourth most widely used energy source in industry, following electricity, natural gas, and water. However, producing compressed air is not as efficient as it may seem. In fact, it’s one of the most energy-intensive resources in industrial settings, consuming a significant portion of a facility’s electricity.

The true cost of compressed air

While most industries recognize the value of compressed air, few fully grasp its hidden costs. On average, compressed air accounts for 13% of industrial electricity consumption in countries like France, with similar figures worldwide. But what’s surprising is that more than 90% of the electrical energy used in air compression is lost—primarily in the form of heat—leaving only 8-10% of the energy to perform useful mechanical work. The rest is simply wasted.

For facilities that run compressors 6,000 to 8,000 hours annually, energy consumption can constitute up to 80% of the total cost of compressed air production over five years. When one considers that a cubic meter of compressed air at 7 bar requires 200 Wh to produce, it’s easy to see why inefficiencies like leaks become so expensive.

The hidden drain

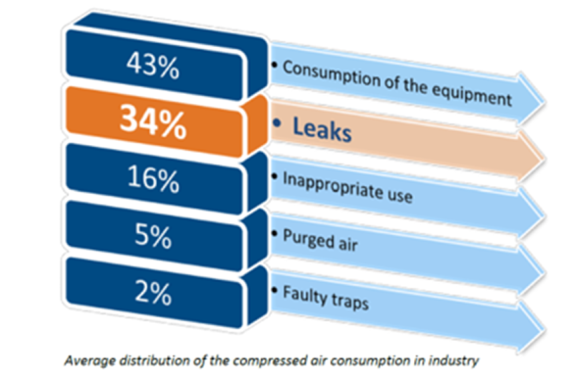

One of the biggest contributors to this inefficiency is the presence of leaks within the compressed air system. While leaks don’t typically pose safety risks or directly disrupt production, they are a major source of energy waste. On average, 30-40% of compressed air production is lost through leaks. In some cases, this number can be even higher. Globally, the average leakage rate is estimated at 34%. This means that one out of every three compressors in a facility could be working just to supply the air lost through leaks—an unacceptable waste of energy and money.

Because leaks are odorless, invisible, and often inaudible in noisy industrial environments, they frequently go unnoticed. But the financial impact of these leaks is significant. Not only do they contribute to skyrocketing energy costs, but they also increase the wear and tear on compressors, leading to more frequent maintenance and shorter equipment lifespans.

SDT340: The solution to compressed air leaks

The SDT340 ultrasound detector is a powerful tool designed to address this costly problem. Using advanced ultrasound technology, the SDT340 allows maintenance teams to detect and locate leaks with precision, even in challenging environments. Here’s how it works:

- Ultrasound detection: Leaks generate ultrasound signals due to the turbulence of air or gas escaping through a small opening. While these signals are beyond the range of human hearing, the SDT340 can detect them and convert them into audible frequencies using heterodyne technology. This makes it possible for technicians to hear and locate leaks that would otherwise go unnoticed.

- User-friendly features: The SDT340 is equipped with an intuitive interface, Bluetooth headphones, and easy-to-navigate software integration with Ultranalysis® Suite 3 (UAS3). This makes it simple to use in the field, providing real-time data and visuals that guide technicians toward the exact location of leaks.

- Pinpoint accuracy: Unlike traditional leak detection methods, such as using soapy water or listening for hissing sounds during production shutdowns, the SDT340 offers precise and efficient detection in live environments. It can identify leaks of all sizes and pressures, ensuring that even the smallest air leaks are located and addressed.

- Versatility: Beyond compressed air, the SDT340 is capable of detecting gas leaks, steam trap issues, and problems in hydraulic and pneumatic systems, making it a versatile tool for any plant’s condition monitoring strategy.

Immediate ROI: Why leak detection is a priority

Identifying and repairing compressed air leaks is one of the most cost-effective strategies for improving energy efficiency in industrial settings. Unlike other optimization measures, such as installing variable speed controls or upgrading equipment, leak detection requires minimal investment and delivers immediate returns.

Training a maintenance team to use the SDT340 takes just a few hours, after which leak detection can be incorporated into regular maintenance routines. The result is often a drastic reduction in energy consumption, with plants saving thousands or even tens of thousands of euros annually by fixing leaks that previously went undetected.

How much can you save?

To put the savings into perspective, consider that the production of a cubic meter of compressed air at 7 bar consumes

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français