STEUTE

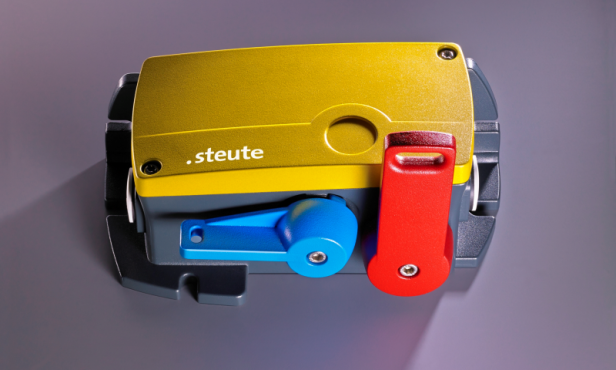

Wireless toggle switch for Intralogistics: RF RW-NET

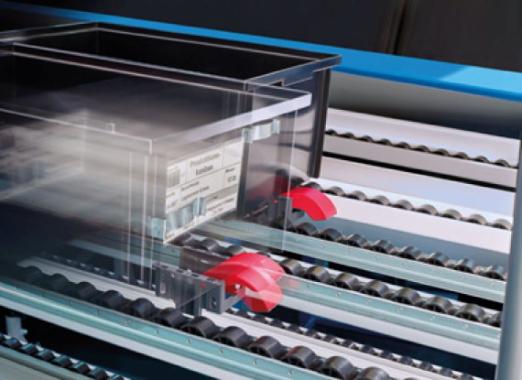

The RW-NET RF wireless rocker sensor detects the presence of a container on a roller conveyor, e.g. in a Kanban rack, and sends an automatic replenishment request via the access points of the sWave.NET® radio network to the customer's IT network. The strong demand for network-enabled switching devices in E-Kanban racks is driving this new development.

So far, steute has responded to this demand for wireless switches from the sWave.NET® standard program with wireless actuators, position switches and optical sensors. With the RF RW-NET, a switching device is now available, which was developed from the start for e-kanban applications and which also offers a commercial advantage: the network-integrable position sensor has been designed with real optimization in mind. costs . It is not only suitable for applications in Kanban racks, but also, for example, for filling level detection in conveyor systems. In practice, a weighted rocker is used as an actuator and the internal sensor registers its position. The angle of inclination and the switching hysteresis, which determine the triggering of the signal, can be set in the sWave.NET® software. Using a universal snap-in element, the position sensor can be mounted tool-free on roller conveyors or shelves from leading manufacturers with very little effort. The access points, which function like a router, receive signals from wireless equipment, aggregate them and transmit them over Ethernet or Wi-Fi, to the materials management software or the production planning department (CAM). In this way, restocking requests are automatic. The application server contains a database, provided by steute, which collects all the information in the field before transferring it, either directly or through middleware, to the client's IT platform (ERP, acquisition of production data, condition monitoring system, inventory management system, etc.) and, if necessary, also via web services, to multi-site IT systems or the cloud. This ensures fast and continuous communication, from every relevant switching device in the warehouse, commissioning site or production plant, to the corporate IT infrastructure.

- Sensor with sWave.NET® radio technology for detecting small parts bins

- Easy assembly in standard commercial shelves

- Universal support for various manufacturers of roller conveyors, e.g. item, CREFORM, Rollex etc.

- Configurable transmission intervals L

AREAS :

- Logistics / Supply chain management

- Supplies / Industrial equipment

- Workshop machines / Machine tools (equipment and associated services)

Français

Français